Infrared thermal imaging electrical hidden fire detection method

Introduction

With the development of economic construction and the improvement of people's living standard, grow with each passing day quantity of various kinds of electrical equipment, there exist many problems, the quality of electrical products, engineering design, installation and operation etc., finally focuses on the performance of the existence of some electrical hazards and risks of electrical fire electrical equipment and wiring operation, easily lead to fire, cause heavy property losses and heavy casualties.

Therefore, the fire safety inspection, electrical safety testing of electrical equipment and wiring, electrical fire hazard exists to determine the location and severity, to take timely measures to eliminate hidden dangers, can effectively prevent and reduce the occurrence of electrical fire. An important means of infrared detection technology is the electrical safety testing.

Infrared detection technology is the basis for the development of a new comprehensive technology in Infrared Physics, electronics and computers as infrared light, it is widely used in many fields of military, electric power, petrochemical, metallurgy, medicine etc.. In recent years, in the electrical fire safety inspection, found that the electrical fire hazards, prevention and reduction of electrical fire accidents have achieved remarkable results.

The principle of 1 Infrared Detection Technology

Infrared light is an electromagnetic wave, the wavelength range of 0.76 ~ 1000 m, are no longer visible. Any temperature above absolute zero (273.15 C) object, is constantly emitting infrared radiation. According to Stephen Boltzmann's law, the temperature for the T object, the radiant power emitted per unit area is

P = epsilon Sigma T4 (1)

Among them:

P - radiation power per unit area (W);

E - object surface emissivity;

Sigma - Stephen Boltzmann constant, the value of which is 5.673 x 108W / (m2K4);

T - the object surface temperature (K).

From the type, surface temperature higher, radiation power per unit area of the greater. When the surface temperature of known objects and its emission rate, the radiation power of the object can be calculated according to the formula. Conversely, if the radiation power emitted by objects measured, can use the formula to determine the object surface temperature.

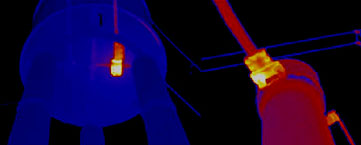

As we know, electrical equipment will be heating in normal operation, the process of the formation and development of electrical fault, the vast majority are related with heating. The user use electrical equipment in the process of conducting circuit part, the presence of a large number of joints, the contact or connection, if the conductive loop connection failure can be caused by the contact resistance is too large, when the load current through, will inevitably lead to local overheating; if the insulation of electrical equipment aging or damaged, will cause insulation dielectric loss is too large and in the operating voltage of the role, will produce overheating; in addition, optionally installed electrical equipment, also can make the conductor ampacity is too large to overheat, these overheated office has become the hidden danger of electrical fire.

2 infrared detecting instrument

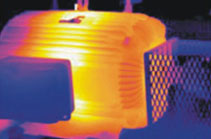

Infrared radiation energy of the infrared detection equipment can detect the overheating hidden fire emit, and convert it into a corresponding electrical signal, through the electrical signal processing system specialized for processing, finally by the imaging device to obtain thermal map should be relatively and surface temperature of the object, determine the hot spot location and temperature. This is the infrared detection technology of electrical fire hazard detection basis.

Infrared detecting instrument is varied, commonly used at present in our country fire protection work has three kinds, namely infrared thermometer, infrared thermal television, infrared thermal imager.

Detection and judgment of 3 electric fire hazard

Detection of infrared detection technology is mainly used in overheating fire hazards and determination.

Detection of 3.1 electrical fire hazards

Electrical fire hazard detection process is generally four steps:

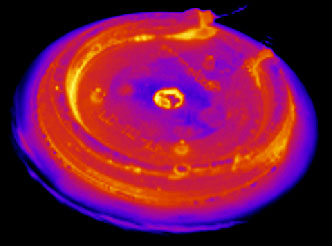

(1) of electrical equipment and wiring general to conduct a comprehensive scan widely examined using infrared thermal television or thermal imager, found that the abnormal heating parts. The heating position intake thermography focus on electric equipment and line;

(2) for temperature measurement of abnormal heating parts by infrared thermometer. When measuring temperature, should first correct choice of the measured object surface emissivity, select the appropriate reference to determine the environmental temperature, environmental temperature, relative humidity and type a measurement distance compensation parameter and select the appropriate temperature range;

To the same measuring object from different orientations were measured to find the highest hot temperature value, measuring the temperature of the measurement object different should keep distance uniformity and range;

(3) the actual surface temperature record abnormal heating electrical equipment, heating parts of the load current and environmental temperature;

(4) on the thermal images of the temperature field by computer analysis and processing.

Method to determine the 3.2 electrical fire hazards

3.2.1 temperature judgment method

According to the surface temperature of the heating position of electrical device of infrared thermometer measured, meanwhile considering the load rate and the connection part of the contact resistance of the electrical fire, the analysis of possible existence of hidden dangers.

This method is put forward to eliminate the necessary effect of different load and environmental temperature on the infrared judgment result of the. When the ambient temperature is low, especially the load current is small, the temperature of equipment value does not exceed the standard, but a large number of facts prove this when the temperature does not mean that the device has no defect or fault exists, often in the load growth, or the environment temperature rises, it will lead to the accident of the equipment, the formation of electrical fire hazard. So the current type of equipment can also be to determine the existence of hidden or not by adopting relative temperature difference method.

"The relative temperature difference" refers to the status of the equipment the same or substantially the same (of equipment type, installation location, environment temperature, surface condition and the load current and so on) the measured temperature difference between two corresponding points, and the ratio among the more heat measuring point temperature rise, the mathematical expressions for the

Delta tau (%) = (T 1 - T 2) / tau 1 x 100 (%) (3)

Among them:

R 1 - high temperature measuring point temperature rise, (C);

R 2 - low temperature measuring point temperature rise, (C).

Usually, when the delta tau = 35%, can diagnose the equipment defects, should be tracking and monitoring, when necessary to plan maintenance.

3.2.3 similar comparative method

The same comparison is a comparison between similar devices, the so-called "similar" equipment refers to three of the same type equipment with a loop and the same equipment, namely their condition, same temperature than the same type equipment, are usually called "vertical comparison and horizontal comparison". Specific approach is to similar equipment in the corresponding part of the temperature values are compared, it is relatively easy to determine whether the device is normal. In comparing like with like, should be careful not to rule out the possibility that the three-phase equipment also produces thermal fault, although the incidence rate is very low. The scope of application of similar comparative method widely, including the current type and voltage type equipment, including diagnosis of internal and external fault.

4 Conclusion

Infrared detection technology has many advantages, such as: test does not contact the electric equipment, do not influence ordinary work, can accurately and visually display the location and severity of electrical fire hazard, and can carry on analysis of computer science to make electrical fire hidden trouble diagnosis conclusion, and has the advantages of simple operation, fast detection speed and high working efficiency, strong safety detection, can keep a safe distance from electrical equipment, wide application range, can be used for various types of electrical equipment and power distribution line inspection. However, because the infrared detection instrument are surface temperature, and electrical equipment internal temperature because of the complex structure can not be accurately measured, so it must be combined with other measurement technology and scientific methods to better play its role. In addition, infrared detection technology is mainly for the detection of fire hazards to overheat, electric spark type electric fire hazard should adopt the ultrasonic detection.

Infrared detection technology has now developed into a high-profile high-tech, along with the social production and life of the modernization process accelerated, as a means of detection of electrical fire indispensable, infrared detection technology will be used more widely.

红外热成像电气隐患防火检测方法

简介

随着经济建设的发展和人民生活水平的提高,各种电气设备数量的与日俱增,电气产品质量、工程设计施工安装和运行管理等方面存在的诸多问题,最终集中表现为电气设备和线路运行中存在某些电气事故隐患和电气火灾隐患,极易酿成火灾,造成惨重的财产损失和重大的人员伤亡。

因此,在防火安全检查中,对电气设备和线路进行电气安全检测,判定电气火灾隐患的存在部位和严重程度,及时采取措施排除隐患,可以有效地防止和减少电气火灾的发生。红外检测技术就是电气安全检测的一种重要手段。

红外检测技术是以红外物理学、红外光电子学和电子计算机为基础发展起来的一门新兴的综合性技术,它广泛应用于军事、冶金、电力、石化、医药等多个领域。近几年,在电气消防安全检测,发现电气火灾隐患,防止和减少电气火灾事故方面也取得了显著的成效。

1 红外检测技术的原理

红外线是一种电磁波,它的波长范围为0.76~1000μm,不为肉眼所见。任何温度高于绝对零度(-273.15℃)的物体,都会不断地发射红外辐射。根据斯蒂芬—玻尔兹曼定律,温度为T的物体,单位面积所发射的辐射功率是

P=εσT4 (1)

其中:

P——单位面积辐射功率,(W);

ε——物体表面发射率;

σ——斯蒂芬—玻尔兹曼常数,其数值为5.673×10-8W/(m2K4);

T——物体表面温度,(K)。

从上式可知,物体的表面温度越高,单位面积的辐射功率就越大。当已知物体的表面温度和它的发射率时,按上式就可计算出物体的辐射功率。反之,如果测定了物体所发射的辐射功率,就可以利用上式确定物体表面的温度。

我们知道,电气设备在正常运行时均会发热升温,电气故障形成和发展的过程,绝大多数都与发热升温有关。用户使用电气设备过程中,导电回路部分存在大量的接头、触头或连接件,如果导电回路连接处发生故障,就会引起接触电阻过大,当负荷电流通过时,必然导致局部过热;如果电气设备的绝缘层出现老化或破损,将 造成绝缘介质损耗过大,在运行电压的作用下,会产生过热;另外,随意装接用电设备,也会使导线因载流量过大而出现过热现象,这些过热处就成为了电气火灾的隐患。

2 红外检测仪器

红外检测仪器可以检测到这种过热型火灾隐患发射出的红外辐射能量,并将其转换成相应的电信号,经过专门的电信号处理系统进行处理,最后再经成像装置得到与物体表面温度相对应的热像图,确定过热点位置和温度。这就是红外检测技术检测电气火灾隐患的依据。

红外检测仪器多种多样,目前在我国消防工作中普遍应用的有三类,即红外测温仪、红外热电视、红外热像仪。

'

'

3 电气火灾隐患检测和判断方法

红外检测技术主要应用于过热型火灾隐患的检测和判定。

3.1 电气火灾隐患的检测

电气火灾隐患的检测过程一般为四个步骤:

(1)使用红外热电视或热像仪对一般的电气设备和线路进行全面扫描普遍检查,发现其异常发热部位。对重点电气设备和线路的发热部位摄取热像图;

(2)用红外热温仪对异常发热部位进行测温。测温时,应首先正确选择被测物体的表面发射率,选择适当的参照物确定环境温度,键入环境温度、相对湿度和测量距离等补偿参数并选取适当的温度范围;

对同一测量对象应从不同的方位进行测量找出最高发热点的温度值,对不同的测量对象进行测温时应保持距离一致和方位一致;

(3)记录异常发热电气设备的实际负载电流、发热部位的表面温度以及环境温度;

(4)利用计算机对热像图的温度场进行分析处理。

3.2 电气火灾隐患的判定方法

3.2.1 温度判断法

根据红外测温仪测得的电气装置发热部位的表面温度,同时考虑负载率和连接部分接触电阻的情况,分析可能存在的电气火灾隐患。

必要 此法是为排除负荷及环境温度不同时对红外判断结果的影响而提出的。当环境温度低,尤其是负荷电流小的情况下,设备的温度值并没有超过规范标准,但大量事实证明此时的温度值并不能说明该设备没有缺陷或故障存在,往往在负荷增长之后,或环境温度上升后,就会引发设备事故,形成电气火灾隐患。故对电流型设备还 可采用“相对温差”法来判别隐患存在与否。

“相对温差”是指设备状况相同或基本相同(指设备型号、安装地点、环境温度、表面状况和负荷电流等)的两个对应测点之间的温差,与其中较热测点温升的比值,其数学表达式为

Δτ(%)=(τ1-τ2)/τ1×100(%)(3)

其中:

τ1——温度较高测点的温升,(℃);

τ2——温度较低测点的温升,(℃)。

通常,当Δτ≥35%时,就可以诊断该设备存在缺陷,应予以跟踪监测,必要时要安排计划检修。

3.2.3 同类比较法

同类比较法是指在同类设备之间进行比较,所谓“同类”设备的含义是指同一回路的同型设备和同一设备的三相,即它们的工况、环境温度相同可比时的同型设备,通常也称做“纵向比较”和“横向比较”。具体作法就是对同类设备的对应部位温度值进行比较,可以比较容易地判断出设备是否正常。在进行同类比较时,要 注意不能排除有三相设备同时产生热故障的可能性,虽然这种情况出现的几率相当低。同类比较法适用范围广,包括电流型和电压型设备,也包括对内、外部故障的诊断。

4.结束语

红外检测技术具有很多优点,如:测试时不接触用电设备,不影响受检单位的正常工作,能够准确、直观地显示电气火灾隐患部位和严重程度,且可以进行计算机分析,科学地做出电气火灾隐患诊断结论,并具有操作简便、检测速度快、工作效率高、安全性强、检测时可与用电设备保持安全距离,适用范围广,可用于各类型 用电设备及配电线路的检查等。但是,由于红外检测仪器测量的都是物体的表面温度,而电气设备内部的温度因结构复杂而不能准确地测出,所以必须与其他测量技术和科学方法结合起来才能更好地发挥它的作用。另外,红外检测技术主要针对过热型火灾隐患的检测,对于电火花型电气火灾隐患应采取超声波检测。

红外检测技术现已发展成一门倍受瞩目的高新技术,随着社会生产和生活现代化进程的加快,作为电气防火不可缺少的检测手段,红外探测技术必将得到更加广泛的应用。