Infrared Thermography Imaging Surveys service inspection maintance testing electrical scanning at china NKAUTOMATIC

Infrared thermal imaging preventive service to electrical hazards

Infrared thermal imaging preventive testing services, nondestructive detection, electrical ultrasonic testing services,

, fire hazard. Electrical preventive troubleshooting, maintenance switch, transformer maintenance

Introduction to the

With the development of economic construction and the improvement of people's living standard, all kinds of increasing the number of electric equipment, power load increasing, part of the electrical equipment in the overload or overage run, so many problems, finally focused performance for some problems in the operation of the electrical equipment and wiring electrical accident hidden danger, cause serious damage to property and significant casualties.

Therefore, in the security check, electrical safety testing of electrical equipment and wiring, to determine the existence of the electrical fault hidden trouble location and severity, take timely measures to eliminate hidden dangers, can effectively prevent and reduce the electric accident. Infrared detection technology is an important means electrical safety testing.

Infrared detection technology based on infrared physics, infrared light, electronics and computer developed on the basis of a new comprehensive technology, it is widely used in military, metallurgy, electric power, petrochemical, medicine and other fields. In recent years, the electrical safety inspection, found that electrical hazards, to prevent electrical accident prevention and also has obtained the remarkable result.

We know that in the normal operation of all electrical equipment will be fever heat, electrical failure process of the formation and development, most of them are related to the heating temperature. Users use electrical equipment in the process, the conductive circuit part, contact, or the presence of large amounts of joint fittings, if conductive loop connection fails, will cause the contact resistance is too large, when the load current through, will lead to local overheating; If the electrical equipment insulation aging or damaged, will cause the insulation dielectric loss is too big, under the action of running voltage, will produce overheating; In addition, casual assembling electric equipment, also can make wire overheating due to carrying capacity is too large, the overheating became electrical safety hidden trouble.

1 the principle of infrared detection technology

Infrared light is an electromagnetic wave, its wavelength range of 0.76 ~ 1000 microns, the naked eye can see. Any temperature above absolute zero (273.15 ℃), will constantly launch infrared radiation. According to Stephen - boltzmann's law, the temperature of the T objects as, radiation power is emitted per unit area

P = epsilon sigma T4 (1)

Among them:

P - radiation power per unit area, (W);

Epsilon - surface emissivity;

Sigma - Stephen - boltzmann constant, the value of 5.673 x 10-8 w/(m2K4);

T - an object's surface temperature, (K).

From the type, the surface temperature is higher, the greater the radiation power per unit area. When the surface temperature of the known object and its emissivity, the object can be calculated according to the type of radiation power. On the other hand, if the determination of the radiant power emitted by an object, you can use the type to determine the temperature on the surface of the object.

2 infrared testing instrument

Type infrared testing instrument can detect this overheating hidden emit infrared radiation energy, and convert them to corresponding electrical signal, specially in the electrical signal processing system for processing, and then by the imaging device with surface temperature corresponding to the thermal diagram, determine the hot spot location and temperature. This is the basis of the infrared detecting technology in electrical hazards.

Various infrared testing instruments, at present in our country, there are three kinds of commonly used in fire control work, namely, infrared thermometer, infrared TV, infrared thermal imager.

3 electrical hazard detection and judgment method

Type infrared detection technology is mainly used in overheating hidden trouble detection and judgment.

3.1 electrical hazard detection

Electrical hazards detection process generally into four steps:

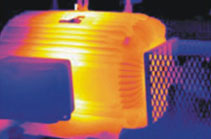

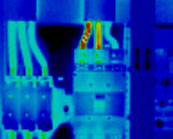

(1) the use of thermal infrared thermal imager and television to general electrical equipment and wiring to conduct a comprehensive scan general inspection, found that the abnormal heating area. Hot parts for the main electrical equipment and wiring to absorb heat like figure;

(2) using thermal infrared thermometer for temperature abnormal hot parts. Temperature measurement, shall, first of all, correct selection of measured surface emissivity of the object, select the appropriate reference to determine the environment temperature, type the environment temperature, relative humidity and measure the distance compensation parameters and select the appropriate temperature range;

Measure to measure the same object from different directions to find the most hot spot temperature, temperature measurement with different measuring objects should be consistent distance and azimuth;

(3) record abnormal fever actual load current of electrical equipment, hot parts of the surface temperature and environmental temperature;

(4) using the computer to hot like figure of temperature field is analyzed.

3.2 electrical hazard determination methods

3.2.1 temperature judgment method

According to the infrared thermometer hot parts of the surface temperature of the electric devices, at the same time, considering load rate and the connection part of the contact resistance, analysis of possible electrical hazards.

This method is to eliminate load and environmental temperature are different of the influence of the infrared judgment result. When the environment temperature is low, especially under the condition of small load current, temperature of equipment does not exceed the standard, but a large number of facts prove that the temperature there is no defect or failure does not mean that the equipment, often after load growth, or after temperature rise, will cause equipment accident, formation of electrical hazards. So the type of current equipment but also the relative temperature difference method is used to distinguish hidden trouble or not.

"The relative temperature difference" refers to the equipment condition of the same or basically the same (refers to the equipment type, installation location, environment temperature, surface condition and load current, etc.) of the temperature difference between two corresponding points, and which is the ratio of hot point temperature rise, its mathematical expression for

Δ tau (%) = (1 - tau tau 2)/tau 1 x 100 (%) (3)

Among them:

Tau 1 - the rise of temperature of the high temperature measuring point, (℃);

Tau 2 -- the rise of temperature of the low temperature measuring point, (℃).

Usually, when Δ tau 35% or more, can diagnose the defective equipment, must be paid to the monitoring, when necessary to arrange plans to overhaul.

3.2.3 the similar comparison method

Similar comparative law refers to the comparison between similar equipment, the meaning of "similar" equipment refers to the same loop of the same type of equipment and the same phase, namely, their working condition, environment temperature is the same than the same type of equipment, are usually called "longitudinal comparison" and "horizontal". Specific approach is to compare the temperature corresponding parts of similar equipment, can be relatively easy to determine if the equipment is normal. When comparing the similar, should pay attention to can't rule out the possibility of three-phase equipment producing hot fault, although the chances of getting this kind of situation is relatively low. The similar comparison method applicable scope is wide, including current type and voltage type equipment, including internal and external fault diagnosis.

4. The conclusion

Infrared detection technology has many advantages, such as: test without contact with electricity equipment, does not affect the normal work of the tested units, able to accurately and intuitively show the electrical hazard area and severity, and can undertake computer analysis, scientifically make electrical hidden trouble diagnosis, and has simple operation, fast detection, high efficiency, safety, and can keep a safe distance from electrical equipment when testing, the applicable scope is wide, can be used for each type Electrical equipment and power distribution line inspection, etc. However, because of the infrared detecting instrument measurement is the surface temperature of the object, and the temperature inside the electrical equipment because of its complex structure and cannot be accurately measured, so should be combined with other measurement technology and scientific methods to better play its role. In addition, the infrared detection technology is aimed at detection of bidden danger of overheating type for edm type electrical hazards should be taken to the ultrasonic detection.

Infrared detection technology has developed into a high-profile high and new technology, along with the social production and life of modernization is accelerated, as indispensable to electrical faults detection means, the infrared detection technology will get more extensive application. In Shanghai nanjing wujiang, suzhou, kunshan, taicang, jiangsu changzhou, wuxi yixing ZhuJiaXing yangzhou zhejiang huzhou taizhou zhenjiang nantong hangzhou ningbo cixi shaoxing shengzhou jinhua yiwu infrared testing services wenzhou, taizhou lishui zhoushan quzhou, Beijing tianjin hebei baoding shijiazhuang, xingtai, tangshan, cangzhou chengde zhangjiakou qinhuangdao in Inner Mongolia, hainan haikou yunnan kunming, guiyang, guizhou, fujian fuzhou, xiamen, shandong province, jinan, Qingdao, changsha, hunan zhuzhou yiwu with permanent offices, such as for has been prepared to serve you anytime and anywhere in shenzhen guangzhou shaoguan zhuhai shantou foshan, jiangmen, zhanjiang maoming zhaoqing huizhou meizhou shanwei heyuan yangjiang qingyuan dongguan zhongshan chaozhou jieyang yunfu shenzhen chiwan yantian, guangzhou cixi, ningbo zhenhai zhoushan Shanghai baoshan waigaoqiao yangshan Qingdao in shandong jinan yiwu in hangzhou, zhejiang province, fujian xiamen electric power, power supply, electricity, telecommunications, petrochemical, steel, tobacco, aviation, aircraft, such as construction firms provides preventive infrared thermal imaging testing services, electrical ultrasonic testing services, nondestructive detection, fire hazard. Electrical preventive troubleshooting, maintenance switch, transformer maintenance service to serve you anytime and anywhere

We have thermography imaging equipment and ultrasonic inspection

equipment, have professional personnel inspection technology, through

the Infrared Traning Center training. We are dedicated to provide you

with professional/ fast/perfect/ infrared thermal imaging technology

and ultrasonic inspection service, online diagnostic equipment

reliability and safety, to help customers make preventive maintenance.

Thermal imaging detection /ultrasonic detection/ fault prevention

Thermography inspection can capture, emitted by other methods do

not see (IR) radiation heat. These images can show the temperature

range in color and color change that, observers can find high

temperature may herald the electrical, mechanical or process problems

(or low temperature point), namely the temperature defect. Therefore,

the equipment fault recognition will occur and to prevent its

occurrence, will bring the lower production cost and less maintenance.

Ultrasonic detector can detect ultrasonic due to abnormal discharge

device sends out, especially the switch device enclosed in operation,

with the use of ultrasonic detection and infrared detection, can be

more accurate and serious fault identification of various, more

significant effect.

Thermal imaging detection

/ultrasonic inspection / use scope

Electrical equipment:

Malfunction of heating rotary motor, transformer, circuit breaker,

transformer, power capacitors, lightning arrester, power cable, bus,

conductor, insulator, switchgear, low voltage electrical and two loop

detection

Professional equipment:

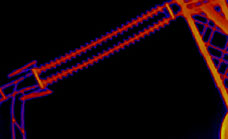

Detection of valve and steam valve, bearing and mechanical parts

detection, detection of heat exchanger, boiler and condenser,

compressor testing, aircraft, ship detection equipment

at China Port Chiwan Yantian Ningbo Shanghai Tianjin QINGDAO Xiamen

Chemical equipment:

Various reaction device, thermal insulation pipes, storage tank, heat

preservation equipment

Infrared thermal imaging & Ultrasonic detection to the client

proceeds:

1、find the potential hidden trouble of equipment

2、save repair costs, improve the repair efficiency, shorten the

repair time and cycle

3、improve the company's repair management level