Electronic photoelectric current transformer voltage]

Medium voltage electronic voltage transformers OEM/ODM

An overview,

NK - PAC single-phase dry type voltage transformer, voltage transformer is suitable for rated frequency of 0.5 Hz - 1 MHZ, rated voltage 10 kv measuring system, under the wide linear range, good dynamic performance, a voltage measurement, monitoring, the transient protection.

Second, the model meaning

Voltage transformer model encoding rules

Company code number classification principle of ac/dc voltage level

NK P A communication C capacitance type annotation, according to the actual voltage grade unit: V. KV.

D type dc resistance R

B O photoelectric ac/dc

Company code number + classification, ac/dc, principle of precision grade "+" + voltage grade separated by "-"

Accuracy of 0.1 to 5%, and 5% expressed in 02, 1% in 10 said

Example: NK PAC05-10 kv voltage transformer said 10 kv ac capacitance pressure precision (0.5%)

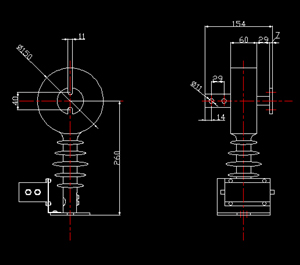

Three, the structure profile

The voltage transformer is electronic transformer, consists of two parts, sensor and processing circuit, the circuit should be stable source of power supply, DC power supply voltage + 15 v DC (ripple is less than 50 mv). Sensing part adopts the principle of capacitance sensor, its wide linear range, good dynamic performance, no iron core, a second signal with no direct electrical connection between primary voltage, the shield pillar type structure can effectively curb outside electromagnetic field effects on the system under test.

Four, the technical parameters

NK - PAC10-10 kv model

A rated voltage 10 kv, can be adjusted according to customer's specific requirements

Secondary rated output voltage is 4 v or digital optical signals, can be adjusted according to customer's specific requirements

Measurement accuracy up to 0.2/3 p

Or 2 k ohm load requirements

Insulation level of 12/42/75 (kV)

Output linearity UI 20% - 150% UI, better than 0.5%

Response time is better than 5 us, (TYP, du/dt = 10 kv / 5 us)

Output performance - 25 to + 50 ℃ temperature within the scope of change is less than + / - 0.2%

Zero offset voltage plus or minus 10 mv

Zero offset voltage temperature performance plus or minus 10 mu V / ℃

Power supply + 15 v, ripple voltage less than 50 mv

Medium voltage tubular (Rogowski) electronic current transformer

Single-phase epoxy resin casting tubular, electronic current transformer is suitable for the rated voltage of current of 10 kv power system monitoring, measurement and transient protection. Its characteristics are as follows:

May 1, as a result of the coil as sensing unit, measuring the wide linear range, measurement range can be up to 40 times and on.

2, high measurement precision, measurement can reach 0.2 S.

3, good dynamic performance, measuring limit to 0.2 Hz, limit to 200 KHZ, therefore to contain large attenuation Dc component can accurately reflect the short circuit current, is suitable for the short circuit current transient process under the 500 ms current measurements. The measure precision of the protection to 5 tpe.

4, when the transformer secondary output and relay protection devices are far apart, with optical fiber digital transmission output signal of the solutions, the second signal with no direct electrical connection between primary voltage, strong ability of resisting electrical transient bursts.

Second, the model meaning current transformer model encoding rules

Company code number classification principle of ac/dc open/closed loop current level

NK C A R tubular C loop according to the actual current levels, unit: A; KA.

D H hall S open-loop dc

B O photoelectric ac/dc

L low power

Company code number + classification, ac/dc, principle, open/closed loop, precision level + current level between "+" with "-" separated years n accuracy of 0.1-5%,

Example: 0.2% expressed in 02, 0.2% expressed in 50

Example: NK - CAR05-1000 - a said hollow rated current 1000 a ac current transformer accuracy (0.5%)

Three, the structure profile

The current transformer is electronic transformer, consists of two parts, sensor and processing circuit, the circuit to be stable power supply, DC source voltage + 15 v DC (ripple is less than 50 mv). Sensing part adopts the principle of Rogowski coil, non core, its wide linear range, measurement range can be up to 40 times or more. Good dynamic performance and is suitable for the rated frequency of 0.5 Hz - 1 MHZ current measurements. Secondary signals using optical fiber digital transmission mode, the second signal with no direct electrical connection between primary voltage, strong resistance to electrical transient bursts.

Technical parameters:

Model NK - CAR

A rated voltage 10 kv

Rated current Can be customized according to user requirements, minimum 20. A, any upper limit

Measuring range 1-40 times and over the rated current

Secondary rated output voltage of 200 mv or digital signal light, can be adjusted according to customer's specific requirements

Measurement accuracy up to 0.2 S / 5 tpe40

Or 2 k ohm load requirements

Insulation level of 12/42/75 (kV)

Measure the band 0.2 Hz - 200 KHZ

Output performance - 25 to + 50 ℃ temperature within the scope of change is less than + / - 0.2%

Zero offset voltage plus or minus 10 mv

Zero offset voltage temperature performance plus or minus 10 mu V / ℃

Power supply + 15 v, ripple voltage is not greater than 30 mv

Arc furnace special large current measurement roche (tubular) coil

A, technical background

The current sensor is dedicated to roche (tubular) coil of eaf current measurements. The stability of arc furnace electric current control is an effective means to assure the electric arc furnace can effect comparing, so the current accurate and reliable measurement plays an important role. The characteristics of the electric current electric arc furnace is as follows:

1, because of its high power electric arc furnace, the output of current transformer is larger, and the wide dynamic range of measurement. If the general transformer secondary short circuit of current transformer, core volume is very large, heavy weight, high cost.

2, in order to achieve good control effect to measure the fast response.

3, easy to install, require the use of forceps type transformer.

Second, the basic principle of measuring:

Tubular coil is also called the Rogowski coil, is first proposed in 1912 by Russian scientists. Unlike traditional CT, Rogowski coil is enameled wire winding evenly on A non-magnetic skeleton made, due to the framework for the ferromagnetic material, in theory, the sensor in the range of A few A to A few hundred thousand Ann still has good linear.

Rogowski coil measurement accuracy depends on a stable mutual inductance constant M. In order to achieve the ideal state of tubular coil, production must follow the following three conditions:

Stitch density on the unit of skeleton length constant; : (how easy is it harder to achieve)

Every turn coil of the center line of the cross section and the vertical; : (how easy is it very difficult to achieve)

Skeleton constant cross-sectional area; Choose the temperature coefficient of good (ease: skeleton material, generally can reach)

These conditions put forward high request of winding process. In fact, even with a high degree of automation of coiling machine, also difficult to meet the above conditions.

The main problem is caused by:

Coil external magnetic field interference is very sensitive, for example, the adjacent interference phase current; The interference of electromagnetic field space; Measured wire is not in the center hole caused by uneven distribution of magnetic field, etc., thus the accuracy of measurement is not high.

The reliability of the coil is not high, due to the coil working temperature range could be as high as 60-100 ℃, cause the uneven distribution of enameled wire winding, stress after stretch beyond a certain limit rupture, causing coil short line, output signal, it is has been practice verification is one of the more common fault.

Although some manufacturers took a winding method and process improvements, such as the problems still didn't get very good solve. The main reason is to use manual winding of Rogowski coil and coil is far under ideal state, as long as it is manual or mechanical winding, the above problems are inevitable.

Three, the company's solution:

The traditional manual winding Rogowski coil manufacturing methods must abandon thoroughly, to overcome the above performance problems, achieve ideal performance of the Rogowski coil.

After years of studying, the company created by the coil in a completely different structure and manufacturing method (has obtained national invention patent, patent no. : ZL 2003 1, 0111625.7), and its technology in the international leading level. By using this method, the coil manufacturing machine was adopted to realize completely, without any artificial operation, also not use copper wire winding, so compared with traditional method of tubular coil, has the following unique performance advantages:

Determined by the original tubular coil structure strong ability to resist electromagnetic interference;

Determined by the original tubular coil structure strong reliability, completely overcome the break line fault;

Excellent temperature stability: within the scope of the up to 100 degrees of temperature change, the measured temperature stability is better than 0.2%.

Measurement precision 1-2 orders of magnitude higher than that of traditional method, measured current small to 10 a, precision can reach 0.2 still;

Four, technical indicators:

A rated current: 30 a. above, any upper limit

Measurement accuracy level: 0.1; 0.2 (S); 0.5 (S); 1

The secondary rated output: two optional:

A: after transmission optical fiber isolation is proportional to the measured current analog voltage signal, and can be adjusted according to user requirements, recommend application in electromagnetic interference is particularly serious applications.

Anti-interference performance: meet four transient (national standard GB/T17626.4 IEC61000-4-4-1998 and national standards), grade A

B: 4-20 ma

Installation method: pliers type, do not need to disconnect the conductor to be tested

Fifth, this product's technical standards

This product meet the technical standards for:

IEC standards: mutual - 8;

National standards: GB/T 20840.8 2007