Prysmian cable accessories 普睿司曼冷缩电缆终端及中间接头

PRYSMIAN 中压冷缩电缆附件手册

PRYSMIAN MV Cable Accessories

普睿司曼电缆有限公司

PRYSMIAN Cable Co., Ltd

Directory

1 20kV and below the cold shrinkable power cable intermediate joint ------------------

2 15kV cold shrinkable cable indoor, outdoor terminal ------------------

3 35kV cold shrinkable power cable intermediate joint ------------------

Medium voltage cable joints

The maximum voltage of Um:24kV

20kV and below the cold shrinkable middle joint type cable

Product Description: -------------------------------------------------------

The ELASPEED series products are PRYSMIAN company exclusive development, development of high-end products, maintaining the leading level in the world in the field of medium voltage cable accessories. Cold technology to PRYSMIAN quality source of excellent design, reliable. The series of products are the main body sole adopts three layer coextrusion technology to make the machining accuracy is high, the structure size is more accurate, more stable quality, the materials used in ethylene propylene rubber by formula special treatment, the excellent electrical and physical properties, suitable for installation in the wider environment.

Scope of application: -----------------------------------------------------------

Application: cable:

Connection of different specifications of the polymer cable -- single core, three core polymer cable (PE, XLPE, EPR)

- conductor size the same or different, round or profiled copper or aluminum conductor

- can be buried and overhead, and laid in the bridge on the metal belt or a metal wire shielding

- extrusion semiconductor shielding layer or a semiconductor with

- insulation voltage up to 24KV

- conductor size: three core 35-400mm2

The single core 35-1000mm2

Armoured or unarmoured --

目 录

1. 20kV 及以下冷缩型电缆中间接头 ------------------

2. 15kV 冷缩型电缆户内、户外终端 ------------------

3. 35kV 冷缩型电缆中间接头 ------------------

中压电缆接头

最高电压 Um:24kV

20kV 及以下冷缩型电缆中间接头

产品简介:-------------------------------------------------------

ELASPEED 系列产品是 PRYSMIAN 公司独家开发、研制的高端产品,在中压电缆附件领域保 持世界领先水平。优异的设计、可靠的质量来源于 PRYSMIAN 的冷缩技术。该系列产品其本体独 家采用三层共挤技术使其加工精度更高,结构尺寸更准确,质量更稳定,其材料采用乙丙橡胶 经过特殊的配方处理,其电气和物理性能优异,适合更广泛的安装环境。

应用范围:-----------------------------------------------------------

适用: 电缆:

-- 连接不同规格的聚合物电缆 -- 单芯、三芯聚合物电缆(PE、XLPE、EPR)

-- 导体尺寸相同或不同,圆形或异型 -- 铜或铝导体

-- 可直埋、架空、及敷设在桥架上 -- 金属带或金属丝等屏蔽

-- 挤出半导体屏蔽层或半导体带

-- 绝缘电压最高至 24KV

-- 导体尺寸: 三芯 35-400mm2

单芯 35-1000mm2

-- 铠装或非铠装

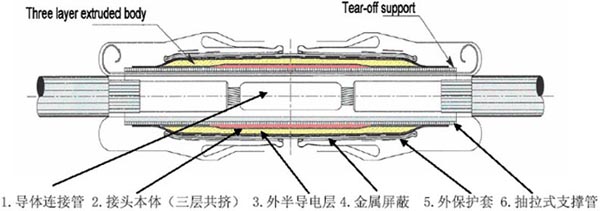

Structure design 结构设计 --------------------------------------------------------

The connecting pipe 2 joint body 1 conductor (three layer coextrusion) 3 outer semi conductive layer 4 metal shield 5 outer protective sleeve 6 pull type supporting tube components function description:

The 1 conductor connecting pipe:

Connect the cable conductor

The 2 connector body:

Consists of three parts, the inner semi conductive shielding electrode (Farad); high dielectric material stress control layer; EPDM insulation layer. After the installation of insulation surface provides uniform persistent radial pressure on the cable, to ensure that its electrical performance.

The 3 outer semi conductive layer: uniform electric field, the restoration of the cable insulation shielding.

The 4 joint metal shield: annular copper braid shield cable metal shield, recovery.

The 5 outer protective sleeve joint sheath protection: there are three ways to choose,

A: heat shrinkable sheathing -- using heat shrinking casing (single core cable can also be directly used Elastic waterproof jacket), outer protection commonly used, has a good waterproof performance.

B: Armored use with protection -- will be insulated waterproof tape and armoring tape wrapped on the joint. The outer protective mode often employed, with waterproof performance and able to bear external mechanical forces.

C: protective casting - casting low density polyurethane. External protection mode under the special environment, has excellent waterproof, anti explosion performance and can bear strong mechanical force.

The 6 supporting tube: pull type spiral.

Product features: -------------------------------------------------------

- product for the whole contraction integration design, all the main material in the factory prefabrication, site operation simpler, easier installation. Reduced because of the risk of operation technology of accident.

Product ontology (inner semiconductor, high dielectric material layer and the insulating layer) using three layer coextrusion technology, compact structure, stable electrical performance, to avoid the traditional casting process to produce blowhole defects, unstable quality.

Production at the same time the online detection of electrical properties of extrusion - ontology, 100% partial discharge test.

Faraday cage - interior design, on the connecting tube winding of any material, insulation end without vertebral type processing.

- material using ethylene propylene rubber and its electrical and physical performance, high tear strength, completely eliminates the silicon rubber materials with on-site installation easy tearing defects.

- body shrinkage is relatively large, a body can be suitable for 2-3 cable specification.

- special ethylene propylene rubber recipe to make body after installation, provide radial pressure lasting for cable, and the cable core with thermal expansion and contraction of a change (and the cable insulation with the breath), does not generate air gap.

Supporting core -- attachment of the exclusive use of both ends of pulling design center positioning accuracy, and reduce the friction support core and a cable core, not easy to break safety.

-- the installation does not need special tools, do not need heating (except the pyrocondensation sheath protection) connection immediately after the use of electricity.

Attachments once installed, winding in cable sheath plugging with two ends outside can make the joint body is completely sealed with a good waterproof performance.

-- usually metal shielding and grounding steel armour uniform. If the user requires shielding, steel armor earthed separately, also can choose to separate grounding mode.

The products are suitable for all kinds of ground environment and all kinds of industrial environment

Quality assurance -------------------------------------------------------

- the company has passed ISO quality system certification of 9001-2000

- the company has passed ISO 14001-2004 environmental system certification

- all products are through 100% test after the factory

Standard ------------------------------------------------------------

This product is in compliance with the following domestic and international standards

JB8144-95; GB12706.4-02; IEC60502-1; ANSI/IEEE404; NFC 33001; DIN 57278

Test ------------------------------------------------------------

This product is based on the domestic standards, in the national authoritative testing organizations - Wuhan High Voltage Research Institute (National Electrical Equipment Quality Inspection Center), by the following test items:

No serial number Testing items testing items of The standard requirements

The requirements of the standard The detection results detection results of The commentary commentary

11 minutes of power frequency voltage test of 45kV, no breakdown of 45kV, 1Min, two combinations of each phase were not qualified specimen breakdown

2 partial discharge test of 15kV lowering power consumption is not more than 10pC two composite sample of each phase of the discharge quantity is less than 1pC qualified

3 load cycle test conductor is heated to 90 to 95 DEG C, each cycle is 8h, wherein the heating cooling 3H 5h, a total of three cycles according to the standard requirements of the completion of the three load cycling tests have the following test evaluation

4 partial discharge test of 15kV lowering power consumption is not more than 10pC two composite sample of each phase of the discharge quantity is less than 1pC qualified

5 impulse voltage test of 105kV, the positive and negative polarity each 10 times, no breakdown of 105kV positive and negative polarity 10 times each, two combinative patterns of each phase were not qualified, breakdown

6 negative 15min DC voltage test of 52kV, no breakdown of 52kV, 15min, two combinations of each phase were not qualified specimen breakdown

7 4H power frequency voltage test of 35kV, no breakdown of 35kV, 15min, two combinations of each phase were not qualified specimen breakdown

8 visual inspection no crack, no deformation and no crack, qualified

---------------------------------------------------------- selection table

Usually the middle 10kV system cable connector selection according to the following section,

Cable section (mm2) core number armoured with external protecting heat shrinkable tube outer protective casting external protection

35-50 single core ETJMe-1C-17-D-T2+Ar ETJMe-1C-17-D-T2+Hs ETJMe-1C-17-D-T2+Re

The three core ETJMe-3C-17-D-T2+Ar ETJMe-3C-17-D-T2+Hs ETJMe-3C-17-D-T2+Re

70-120 single core ETJMe-1C-17-E-T2+Ar ETJMe-1C-17-E-T2+Hs ETJMe-1C-17-E-T2+Re

The three core ETJMe-3C-17-E-T2+Ar ETJMe-3C-17-E-T2+Hs ETJMe-3C-17-E-T2+Re

150-240 single core ETJMe-1C-17-F-T2+Ar ETJMe-1C-17-F-T2+Hs ETJMe-1C-17-F-T2+Re

The three core ETJMe-3C-17-F-T2+Ar ETJMe-3C-17-F-T2+Hs ETJMe-3C-17-F-T2+Re

300-400 single core ETJMe-1C-17-H-T2+Ar ETJMe-1C-17-H-T2+Hs ETJMe-1C-17-H-T2+Re

The three core ETJMe-3C-17-H-T2+Ar ETJMe-3C-17-H-T2+Hs ETJMe-3C-17-H-T2+Re

500-1000 single core ETJMe-1C-17-I-T2+Ar ETJMe-1C-17-I-T2+Hs ETJMe-1C-17-I-T2+Re

* when other voltage system or special type of cable should be based on the cable insulation diameter selection

Packaging ------------------------------------------------------------ this product provides a set of cable connector components required in the packaging box (not including the connecting tube, or by dealers to provide), complete with product instructions, packing list and certificate, the user should be strictly according to the operating instructions for installation and use of the product.

Storage, transportation, installation -----------------------------------------------

This product should be in accordance with the following requirements for storage, transportation and installation.

This product in -10 - 50 degrees in dry indoor environment, storage period of 24 months.

-- transport should rain, extrusion prevention, smashing prevention.

This product should be trained professional installation, installation environment temperature is 0 DEG to 50 DEG C, such as beyond the temperature range of installation, please contact the Prysmian cables Co Ltd.

1.导体连接管 2.接头本体(三层共挤) 3.外半导电层 4.金属屏蔽 5.外保护套 6.抽拉式支撑管 各部件作用描述:

1. 导体连接管:

连接电缆导体

2.接头本体:

由三部分组成,内半导电屏蔽电极(法拉第笼);高介电材料应力控制层;EPDM 绝缘层。安装后 在电缆绝缘表面提供均匀持久的径向压力,以保证其电气性能。

3.外半导电层: 均匀电场,恢复电缆绝缘屏蔽。

4.接头金属屏蔽: 环状铜编织屏蔽,恢复电缆金属屏蔽。

5.外保护套: 接头护套保护有三种方式可供选择,

A:热缩护套 -- 采用热缩护套管(单芯电缆也可直接选用 Elastic 防水护套), 通常采用的外保护方式,具有良好的防水性能。

B:铠装带保护-- 使用时将绝缘防水带和铠装带绕包在接头上。 经常采用的外保护方式,具有防水性能且能承受一定的机械外力。

C:浇铸保护 --- 浇铸低密度聚氨脂。 特殊环境下的外保护方式,具有极好的防水、防暴性能且能承受较强的机械外力。

6. 支撑管:为螺旋抽拉式.

产品特点:-------------------------------------------------------

-- 产品为全冷缩一体化设计,全部主体材料在工厂预制成型,现场操作更简单,安装更容易。降 低了由于操作技术引发事故的风险。

-- 产品本体(内半导体、高介电材料层和绝缘层)采用三层共挤技术,结构紧密,电性能稳定, 避免了传统铸造工艺易产生气孔,质量不稳定的缺陷。

-- 本体挤出生产的同时在线检测电气性能,100%进行局部放电测试。

-- 内部法拉第笼设计,在连接管上不缠绕任何材料,绝缘端部无需椎型处理。

-- 材料采用乙丙橡胶其电气及物理性能优异,抗撕裂强度高,彻底消除了采用硅橡胶材料现场安 装时易撕裂的缺陷。

-- 本体收缩比较大,一个本体可适合 2-3 种电缆规格。

-- 特殊的乙丙橡胶配方使本体安装后,对电缆提供持久的径向压力,且随电缆线芯的热胀冷缩一 同变化(与电缆绝缘同呼吸),不产生气隙。

-- 附件的支撑芯独家采用两端抽拉设计,中心定位准确,且减少支撑芯与电缆线芯的摩擦,不易 断裂安全可靠。

-- 安装时不需要特殊工具,不需加热(热缩护套保护除外)连接后可立即通电使用。

-- 附件一经安装,在电缆护套外缠绕的堵水带能使接头本体两端完全密封.具有良好的防水性能。

-- 通常金属屏蔽和钢铠统一接地。如用户要求屏蔽、钢铠单独接地,也可选择单独接地方式。

-- 本产品适用各种地面环境及各类工业环境

质量保证 -------------------------------------------------------

-- 公司已通过 ISO 9001-2000 质量体系的认证

-- 公司已通过 ISO 14001-2004 环境体系的认证

-- 所有产品均经 100%试验后出厂

标准 ------------------------------------------------------------

本产品符合以下国内和国际相关标准

JB8144-95 ; GB12706.4-02 ; IEC60502-1 ; ANSI/IEEE404 ; NFC 33001 ; DIN 57278

试验 ------------------------------------------------------------

本产品根据国内标准的要求,在国家权威检测机构-武汉高电压研究所(国家电气设备质量检测中 心),通过以下试验项目:

|

No序号

|

Testing items检测项目

|

The standard requirements

标准要求

|

The detection results 检测结果

|

The commentary评注

|

|

1

|

1分钟工频电压试验

|

45kV , 不击穿

|

45kV,1Min,两个组合试样各相均未击穿

|

合格

|

|

2

|

局部放电试验

|

15kV下放电量不大于10pC

|

两个组合试样各相放电量均小于 1pC

|

合格

|

|

3

|

负荷循环试验

|

导体加热至 90∽95℃,每一循环为 8h,其中加热 5h 冷却 3h,共三次循环

|

按标准要求完成三次负荷循环试验

|

有以下试验评定

|

|

4

|

局部放电试验

|

15kV下放电量不大于10pC

|

两个组合试样各相放电量均小于 1pC

|

合格

|

|

5

|

冲击电压试验

|

105kV,正负极性各10次,不击穿

|

105kV正负极性各10次,两个组合式样,各相均未击穿

|

合格

|

|

6

|

负极性 15min 直流电压试验

|

52kV,不击穿

|

52kV,15min, 两个组合试样各相均未击穿

|

合格

|

|

7

|

4h工频电压试验

|

35kV, 不击穿

|

35kV,15min, 两个组合试样各相均未击穿

|

合格

|

|

8

|

外观检查

|

无裂纹,不变形

|

无裂纹,

|

合格

|

选型表 ----------------------------------------------------------

通常 10kV 系统电缆中间接头按以下截面选型,

|

电缆截面(mm2)

|

芯数

|

铠装带外保护

|

热缩管外保护

|

浇铸外保护

|

|

35-50

|

单芯

|

ETJMe-1C-17-D-T2+Ar

|

ETJMe-1C-17-D-T2+Hs

|

ETJMe-1C-17-D-T2+Re

|

|

|

三芯

|

ETJMe-3C-17-D-T2+Ar

|

ETJMe-3C-17-D-T2+Hs

|

ETJMe-3C-17-D-T2+Re

|

|

70-120

|

单芯

|

ETJMe-1C-17-E-T2+Ar

|

ETJMe-1C-17-E-T2+Hs

|

ETJMe-1C-17-E-T2+Re

|

|

|

三芯

|

ETJMe-3C-17-E-T2+Ar

|

ETJMe-3C-17-E-T2+Hs

|

ETJMe-3C-17-E-T2+Re

|

|

150-240

|

单芯

|

ETJMe-1C-17-F-T2+Ar

|

ETJMe-1C-17-F-T2+Hs

|

ETJMe-1C-17-F-T2+Re

|

|

|

三芯

|

ETJMe-3C-17-F-T2+Ar

|

ETJMe-3C-17-F-T2+Hs

|

ETJMe-3C-17-F-T2+Re

|

|

300-400

|

单芯

|

ETJMe-1C-17-H-T2+Ar

|

ETJMe-1C-17-H-T2+Hs

|

ETJMe-1C-17-H-T2+Re

|

|

|

三芯

|

ETJMe-3C-17-H-T2+Ar

|

ETJMe-3C-17-H-T2+Hs

|

ETJMe-3C-17-H-T2+Re

|

|

500-1000

|

单芯

|

ETJMe-1C-17-I-T2+Ar

|

ETJMe-1C-17-I-T2+Hs

|

ETJMe-1C-17-I-T2+Re

|

* 遇其它电压系统或特殊型号电缆应根据电缆绝缘外径选型

包装 ------------------------------------------------------------ 本产品在包装箱内提供一整套电缆接头所需的部件(不包括连接管,或由经销商提供),附有完整 的产品操作说明、装箱单、合格证,用户应严格按操作说明安装使用该产品。

储存、运输、安装 -----------------------------------------------

本产品应按以下要求进行储存、运输、安装。

-- 本产品在-10―50℃室内干燥的环境下,储存期为 24 个月。

-- 运输时应防雨、防挤、防砸。

-- 本产品应由经过培训的专业人员进行安装,安装时环境温度为 0―50℃,如超出该温度范围安装, 请与普睿司曼电缆有限公司联系。

Medium voltage cable terminal

The maximum voltage of Um:17.5kV

15kV cold shrinkable cable indoor, outdoor terminal

Product introduction: ------------------------------------------------------

COLDFIT series cold shrink type terminal is PRYSMIAN company development, development of high-end products, maintaining the leading level in the world in the field of medium voltage cable accessories. Cold technology to PRYSMIAN quality source of excellent design, reliable. The series of products are the stress control part adopts the material with high dielectric constant, and the prefabricated in the body, this design can reduce the cable surface electrical stress effectively, and the insulating performance outstanding, both to protect the cable and simplifies the installation process so that the installation quality is more assured, material silicon rubber used in the electrical and physical properties of excellence, can be installed in the indoor, outdoor, suitable for the installation environment widely.

Scope of application: --------------------------------------------------------- indoor: suitable for indoor ordinary or compact switch cabinet, transformer and other outdoor: suitable for outdoor overhead line, busbar, weather resistance, anti ultraviolet aging.

The application of cable:

Single core, three core polymer cable (PE, XLPE, EPR)

Copper or aluminum conductor

Metal band or a metal wire shielding

- extrusion semiconductor shielding layer or semi conductive screening

- insulation voltage up to 17.5KV

- conductor size three core: Single Core: 50-630mm2 50-400mm2;

Armoured or unarmoured --

Structure design --------------------------------------------------------

Description of each component function:

The 1 conductor terminal: copper or aluminum, using the ring pressed.

The 2 terminal body: adopt silicon rubber material, tracking resistance, anti ultraviolet, hydrophobic, high creepage ability.

The 3 extension pipes: silicon rubber material, to extend the length of installation.

The 4 grounding device: connect the cable shielding and armoring, ground wire leads. Shielding and armoring can separate the ground can also be unified ground.

5 finger: silicone rubber material used for cable port line core bifurcation, sealing the end of the cable

The 6 stress control: to improve the electric field distribution, cable terminal uniform electric field, reduce the electric stress.

The distribution of the electric field: ------------------------------------------------------

Product features: -------------------------------------------------------

- terminal material adopt silicon rubber manufacturing, excellent electrical properties.

The cold shrink type terminal -- is a cable terminal has the advantages of convenient installation, after the installation of insulation surface provides uniform persistent radial pressure on the cable, and with the change of heat expansion and cold contraction cable core together does not generate air gap. In order to ensure its electrical performance. High reliability, excellent performance.

In the manufacturing process, stress control part adopts the material with high dielectric constant, and the prefabricated in the terminal body. This design not only can reduce the cable surface electrical stress effectively, and insulation performance is outstanding, make the installation more concise, more reliable quality.

- in the terminal for use outdoors a waterproof layer of prefabricated, hydrophobic performance is good, the water slide fast.

- don't need special tools, do not need heating installed immediately after the use of electricity.

- can level, tilt installation.

- high creepage ability.

- anti ultraviolet aging.

- body contraction ratio, a body can be suitable for 2-3 cable specification.

Quality assurance -------------------------------------------------------

- the company has passed ISO quality system certification of 9001-2000

- the company has passed ISO 14001-2004 environmental system certification

- all products are through 100% test after the factory

Standard ------------------------------------------------------------

This product is in compliance with the following domestic and international standards

JB8144-95; GB12706.4-02; IEC60502-1; ANSI/IEEE48; VDE0278; HD628

Detect project standard requirements of results in detection of commentary

11 minutes of power frequency voltage test (wet) 45kV, no breakdown of 45kV, 1Min, two combinations of each phase were not qualified specimen breakdown

2 partial discharge test of 15kV lowering power consumption is not more than 10pC 15kV under the composite sample of each phase of the discharge quantity of qualified were less than 2pC

3 load cycle test conductor is heated to 90 to 95 DEG C, each cycle is 8h, wherein the heating cooling 3H 5h, a total of three cycles according to the standard requirements of the completion of the three load cycling tests have the following test evaluation

4 partial discharge test of 15kV lowering power consumption is not more than 10pC 15kV under the composite sample of each phase of the discharge quantity of qualified were less than 2pC

5 impulse voltage test of 105kV, the positive and negative polarity each 10 times, no breakdown of 105kV positive and negative polarity 10 times each, two combinative patterns of each phase were not qualified, breakdown

6 negative 15min DC voltage test of 52kV, no flashover, no breakdown of 52kV, 15min, two combined samples were not at the end of each phase flashover and breakdown of qualified

7 4H power frequency voltage test of 35kV, no flashover, no breakdown of 35kV, 4h, composite sample of each phase were not flashover and breakdown of qualified

---------------------------------------------------------- selection table

Usually 10kV system cable terminal according to the following section selection,

Cable section (mm2) indoor terminal outdoor terminal

The single core type three core type single core type three core type

50~70 CDTI-1C-17-A-T2 CDTI-3C-17-A-T2 CDTO-1C-17-A-T2 CDTO-3C-17-A-T2

95~150 CDTI-1C-17-B-T2 CDTI-3C-17-B-T2 CDTO-1C-17-B-T2 CDTO-3C-17-B-T2

185-240 CDTI-1C-17-C-T2 CDTI-3C-17-C-T2 CDTO-1C-17-C-T2 CDTO-3C-17-C-T2

300~400 CDTI-1C-17-D-T2 CDTI-3C-17-D-T2 CDTO-1C-17-D-T2 CDTO-3C-17-D-T2

500~630 CDTI-1C-17-E-T2 CDTO-1C-17-E-T2

* provides high creepage distance of products, suitable for heavy pollution area, pollution grade IV.

* * in other voltage system or special type of cable should be based on the cable insulation diameter selection

Packaging ------------------------------------------------------------

This product provides a set of cable connector components required in the packaging box (not including the terminal, or by dealers to provide), complete with product instructions, packing list and certificate, the user should be strictly according to the operating instructions for installation and use of the product.

Storage, transportation, installation -----------------------------------------------

This product should be in accordance with the following requirements for storage, transportation and installation.

This product in -10 - 50 degrees in dry indoor environment, storage period of 26 months.

-- transport should rain, extrusion prevention, smashing prevention.

This product should be trained professional installation, installation environment temperature is 0 DEG to 50 DEG C, such as beyond the temperature range of installation, please contact the Prysmian cables Co Ltd.

中压电缆终端

最高电压 Um:17.5kV

15kV 冷缩型电缆户内、户外终端

产品介绍:------------------------------------------------------

COLDFIT 系列冷缩型终端是 PRYSMIAN 公司开发、研制的高端产品,在中压电缆附件领域保 持世界领先水平。优异的设计、可靠的质量来源于 PRYSMIAN 的冷缩技术。该系列产品其应力控 制部分采用高介电常数材料,并将其预制在本体之中,这一设计即能有效的减低电缆表面的电 应力,且具有出众的绝缘性能,既保护了电缆又简化了安装过程使安装质量更有保证,材料采 用硅橡胶其电气和物理性能卓越,可以安装在户内、户外,适合广泛的安装环境。

应用范围: --------------------------------------------------------- 户内:适用于户内普通或紧凑型开关柜,变压器等 户外:适用于户外高架线、母线,耐气候、抗紫外线老化。

适用电缆:

-- 单芯、三芯聚合物电缆(PE、XLPE、EPR)

-- 铜或铝导体

-- 金属带或金属丝屏蔽

-- 挤出半导体屏蔽层或半导电带屏蔽

-- 绝缘电压最高至 17.5KV

-- 导体尺寸三芯:50-400mm2 ;单芯:50-630mm2

-- 铠装或非铠装

结构设计 --------------------------------------------------------

各部件作用描述:

1. 导体端子:铜或铝,采用环形紧压。

2. 终端本体:采用硅橡胶材料,耐电痕、疏水、抗紫外线、高爬电能力。

3. 延长管: 硅橡胶材料,延长安装长度。

4. 接地装置:连接电缆屏蔽及铠装,引出接地线。屏蔽和铠装可单独接地也可统一接地。

5. 分指套: 硅橡胶材料,用于电缆端口线芯分叉,密封电缆端部

6. 应力控制:改善电缆终端的电场分布,均匀电场,降低电应力。

电场分布图:------------------------------------------------------

产品特点:-------------------------------------------------------

-- 终端材料采用硅橡胶制造,电气性能优异。

-- 本冷缩型终端是一种安装方便的电缆终端,安装后在电缆绝缘表面提供均匀持久的径向压力, 且随电缆线芯的热胀冷缩一同变化不产生气隙。以保证其电气性能。可靠性高、性能卓越。

-- 在制造过程中,应力控制部分采用高介电常数材料,并将其预制在终端的本体之中。这一设计 既能有效的减低电缆表面的电应力,而且绝缘性能出众,使安装更简洁,质量更可靠。

-- 在户外使用的终端有预制的防雨层,疏水性能好,水珠滑落快。

-- 不需要特殊工具,不需加热安装后可立即通电使用。

-- 可水平、倾斜安装。

-- 高爬电能力。

-- 抗紫外线老化。

-- 本体收缩比大,一个本体可适合 2-3 种电缆规格。

质量保证 -------------------------------------------------------

-- 公司已通过 ISO 9001-2000 质量体系的认证

-- 公司已通过 ISO 14001-2004 环境体系的认证

-- 所有产品均经 100%试验后出厂

标准 ------------------------------------------------------------

本产品符合以下国内和国际相关标准

JB8144-95 ; GB12706.4-02 ; IEC60502-1 ; ANSI/IEEE48 ; VDE0278 ; HD628

试验 ------------------------------------------------------------

本产品根据国内标准的要求,在国家权威检测机构-武汉高电压研究所(国家电气设备质量检测中 心),通过以下试验项目:

|

序号

|

检测项目

|

标准要求

|

检测结果

|

评注

|

|

1

|

1分钟工频电压试验(湿态)

|

45kV , 不击穿

|

45kV,1Min,两个组合试样各相均未击穿

|

合格

|

|

2

|

局部放电试验

|

15kV下放电量不大于10pC

|

15kv下组合试样各相放电量均≦2pC

|

合格

|

|

3

|

负荷循环试验

|

导体加热至 90∽95℃,每一循环为 8h,其中加热 5h 冷却 3h,共三次循环

|

按标准要求完成三次负荷循环试验

|

有以下试验评定

|

|

4

|

局部放电试验

|

15kV下放电量不大于10pC

|

15kv下组合试样各相放电量均≦2pC

|

合格

|

|

5

|

冲击电压试验

|

105kV,正负极性各10次,不击穿

|

105kV正负极性各10次,两个组合式样,各相均未击穿

|

合格

|

|

6

|

负极性 15min 直流电压试验

|

52kV,不闪络,不击穿

|

52kV,15min, 两个组合试样各相均未闪络和末击穿

|

合格

|

|

7

|

4h工频电压试验

|

35kV, 不闪络,不击穿

|

35kV,4h,组合试样各相均未闪络和击穿

|

合格

|

选型表 ----------------------------------------------------------

通常 10kV 系统电缆终端按以下截面选型,

|

电缆截面(mm2)

|

户 内 终 端

|

|

户 外 终 端

|

|

|

|

单 芯 型 号

|

三 芯 型 号

|

单 芯 型 号

|

三 芯 型 号

|

|

50~70

|

CDTI-1C-17-A-T2

|

CDTI-3C-17-A-T2

|

CDTO-1C-17-A-T2

|

CDTO-3C-17-A-T2

|

|

|

|

|

|

|

|

95~150

|

CDTI-1C-17-B-T2

|

CDTI-3C-17-B-T2

|

CDTO-1C-17-B-T2

|

CDTO-3C-17-B-T2

|

|

|

|

|

|

|

|

185-240

|

CDTI-1C-17-C-T2

|

CDTI-3C-17-C-T2

|

CDTO-1C-17-C-T2

|

CDTO-3C-17-C-T2

|

|

|

|

|

|

|

|

300~400

|

CDTI-1C-17-D-T2

|

CDTI-3C-17-D-T2

|

CDTO-1C-17-D-T2

|

CDTO-3C-17-D-T2

|

|

|

|

|

|

|

|

500~630

|

CDTI-1C-17-E-T2

|

|

CDTO-1C-17-E-T2

|

|

* 可提供高爬距产品,适用于重污染地区,污秽等级 IV 级。

** 遇其它电压系统或特殊型号电缆应根据电缆绝缘外径选型

包装 ------------------------------------------------------------

本产品在包装箱内提供一整套电缆接头所需的部件(不包括端子,或由经销商提供),附有完整的 产品操作说明、装箱单、合格证,用户应严格按操作说明安装使用该产品。

储存、运输、安装 -----------------------------------------------

本产品应按以下要求进行储存、运输、安装。

-- 本产品在-10―50℃室内干燥的环境下,储存期为 26 个月。

-- 运输时应防雨、防挤、防砸。

-- 本产品应由经过培训的专业人员进行安装,安装时环境温度为 0―50℃,如超出该温度范围安装, 请与普睿司曼电缆有限公司联系。

Medium voltage cable joints

The maximum voltage of Um:40.5kV

35kV cold shrinkable middle joint type cable

Product Description: -------------------------------------------------------

The ELASPEED series products are PRYSMIAN company exclusive development, development of high-end products, maintaining the leading level in the world in the field of medium voltage cable accessories. Cold technology to PRYSMIAN quality source of excellent design, reliable. The series of products are the main body sole adopts three layer coextrusion technology to make the machining accuracy is high, the structure size is more accurate, more stable quality, the materials used in ethylene propylene rubber by formula special treatment, the excellent electrical and physical properties, suitable for installation in the wider environment.

Scope of application: -----------------------------------------------------------

Application: cable:

Connection of different specifications of the polymer cable -- single core, three core polymer cable (PE, XLPE, EPR)

- conductor size the same or different, round or profiled copper or aluminum conductor

- can be buried and overhead, and laid in the bridge on the metal belt or a metal wire shielding

- extrusion semiconductor shielding layer or a semiconductor with

- insulation voltage up to 40.5kV

- conductor size: three core 50-400mm2

The single core 50-630mm2

Armoured or unarmoured --

Structure design --------------------------------------------------------

The connecting pipe 2 joint body 1 conductor (three layer coextrusion) 3 outer semi conductive layer 4 metal shield 5 high dielectric with 6 supporting pipe components function description:

1: connect the cable conductor conductor connecting tube

The 2 connector body:

Consists of three parts, a high dielectric material stress control layer; EPDM insulation layer; the outer semi conductive shielding layer. After the installation of insulation surface to provide uniform persistent radial pressure on the cable, to ensure that its electrical performance.

The 3 outer semi conductive layer: uniform electric field, the restoration of the cable insulation shielding.

The 4 joint metal shield: annular copper braid shield cable metal shield, recovery.

5 high dielectric band: improve the potential distribution, uniform electric field.

The 6 supporting tube: the support tube has two kinds of design: a tubular retreat from the type, another kind is spiral pull type.

Product features: -------------------------------------------------------

- product for the whole contraction integration design, all the main material in the factory prefabrication, site operation simpler and easier installation. Reduces the risk of accident due to the operation of technology.

Product ontology (high dielectric constant material layer, insulating layer and the outer semi conductive shielding) using three layer coextrusion technology, compact structure, electrical properties and stability, to avoid the traditional casting process to produce blowhole defects of unstable quality.

Production at the same time the online detection of electrical properties of extrusion - ontology, 100% partial discharge test.

-- on the connecting tube winding of high dielectric constant materials, insulation end without vertebral type processing.

- material using ethylene propylene rubber and its electrical and physical performance, high tear strength, completely eliminates the silicon rubber materials with on-site installation easy tearing defects.

- body shrinkage is relatively large, a body can be suitable for various cable specifications.

- special ethylene propylene rubber recipe to make body after installation, provide radial pressure lasting for cable, and the cable core with thermal expansion and contraction of a change (and the cable insulation with the breath), does not generate air gap.

Supporting core - annex two alternative ways: since the return type, the installation is simpler; pull type, can reduce the installation size. Pull type exclusive use of both ends of pulling design center positioning accuracy, and reduce the friction support core and a cable core, not easy to break safety.

-- the installation does not need special tools, do not need heating (except the pyrocondensation sheath protection) connection immediately after the use of electricity.

Attachments once installed, winding in cable sheath plugging with two ends outside can make the joint body is completely sealed. Has a good waterproof performance.

Usually the metal shield and steel armor unified ground, such as user request shielding, steel armor earthed separately, also can choose to separate grounding mode.

The products are suitable for all kinds of ground environment and all kinds of industrial environment.

Quality assurance -------------------------------------------------------

- the company has passed ISO quality system certification of 9001-2000

- the company has passed ISO 14001-2004 environmental system certification

- all products are through 100% test after the factory

Standard ------------------------------------------------------------

This product is in compliance with the following domestic and international standards

JB8144-95; GB12706.4-02; IEC60502-1; ANSI/IEEE404; NFC 33001; DIN 57278

Test ------------------------------------------------------------

This product is based on the domestic standards, in the national authoritative testing organizations - Wuhan High Voltage Research Institute (National Electrical Equipment Quality Inspection Center), by the following test items:

Detect project standard requirements of results in detection of commentary

11 minutes of power frequency voltage test of 105kV, no breakdown of 105kV, 1Min, two combinations of each phase were not qualified specimen breakdown

2 partial discharge test of 45kV lowering power consumption is not more than 10pC for sample 1 discharge <3pC conformity

Sample 2 discharge <3pC conformity

3 load cycle test conductor is heated to 90 to 95 DEG C, each cycle is 8h, wherein the heating cooling 3H 5h, a total of three times the cycle according to the standard requirements of the completion of the three load cycling tests have the following test evaluation

4 partial discharge test of 45kV lowering power consumption is not more than 10pC for sample 1 discharge <3pC conformity

Sample 2 discharge capacity of <3pC

5 impulse voltage test of 250kV, the positive and negative polarity each 10 times, no breakdown of 250kV positive and negative polarity 10 times each, two combinative patterns of each phase were not qualified, breakdown

6 negative 15min DC voltage test of 156kV, no flashover, no breakdown of 156kV, 15min, two combinations of each phase were not qualified specimen breakdown

7 4H power frequency voltage test of 104kV, 104kV 4h, without breakdown, the combination of each phase were not qualified specimen breakdown

---------------------------------------------------------- selection table

Usually the middle 35kV system cable connector selection according to the following section,

Cable section (mm2) of single core (outer protection heat shrinkable tube) single core (sheathed with protective) three core (outer protection heat shrinkable tube) three core (sheathed with protective)

50~150 RTJM-1C-26/35-IP-T2+Hs RTJM-1C-26/35-IP-T2+Ar RTJM-3C-26/35-IP-T2+Hs RTJM-3C-26/35-IP-T2+Ar

185~500 RTJM-1C-26/35-I-T2+Hs RTJM-1C-26/35-I-T2+Ar RTJM-3C-26/35-I-T2+Hs RTJM-3C-26/35-I-T2+Ar

630 RTJM-1C-26/35-I-T2+Hs RTJM-1C-26/35-I-T2+Ar

* when other voltage system or special type of cable should be based on the cable insulation diameter selection

Packaging ------------------------------------------------------------

This product provides a set of cable connector components required in the packaging box (not including the connecting tube, or by dealers to provide), complete with product instructions, packing list and certificate, the user should be strictly according to the operating instructions for installation and use of the product.

Storage, transportation, installation -----------------------------------------------

This product should be in accordance with the following requirements for storage, transportation and installation.

This product in -10 - 50 degrees in dry indoor environment, storage period of 24 months.

-- transport should rain, extrusion prevention, smashing prevention.

This product should be trained professional installation, installation environment temperature is 0 DEG to 50 DEG C, such as beyond the temperature range of installation, please contact the Prysmian cables Co Ltd.

中压电缆接头

最高电压 Um:40.5kV

35kV 冷缩型电缆中间接头

产品简介:-------------------------------------------------------

ELASPEED 系列产品是 PRYSMIAN 公司独家开发、研制的高端产品,在中压电缆附件领域保 持世界领先水平。优异的设计、可靠的质量来源于 PRYSMIAN 的冷缩技术。该系列产品其本体独 家采用三层共挤技术使其加工精度更高,结构尺寸更准确,质量更稳定,其材料采用乙丙橡胶 经过特殊的配方处理,其电气和物理性能优异,适合更广泛的安装环境。

应用范围:-----------------------------------------------------------

适用: 电缆:

-- 连接不同规格的聚合物电缆 -- 单芯、三芯聚合物电缆(PE、XLPE、EPR)

-- 导体尺寸相同或不同,圆形或异型 -- 铜或铝导体

-- 可直埋、架空、及敷设在桥架上 -- 金属带或金属丝等屏蔽

-- 挤出半导体屏蔽层或半导体带

-- 绝缘电压最高至 40.5kV

-- 导体尺寸: 三芯 50-400mm2

单芯 50-630mm2

-- 铠装或非铠装

结构设计 --------------------------------------------------------

1.导体连接管 2.接头本体(三层共挤) 3.外半导电层 4.金属屏蔽 5.高介电带 6.支撑管 各部件作用描述:

1. 导体连接管: 连接电缆导体

2.接头本体:

由三部分组成,高介电材料应力控制层;EPDM 绝缘层;外半导电屏蔽层。安装后在电缆绝缘表 面提供均匀持久的径向压力,以保证其电气性能。

3.外半导电层: 均匀电场,恢复电缆绝缘屏蔽。

4.接头金属屏蔽: 环状铜编织屏蔽,恢复电缆金属屏蔽。

5.高介电带: 改善电位分布,均匀电场。

6. 支撑管: 支撑管有两种设计:一种为管状自退式,另一种为螺旋抽拉式.

产品特点:-------------------------------------------------------

-- 产品为全冷缩一体化设计,全部主体材料在工厂预制成型,现场操作更简单,安装更容易。降低 了由于操作技术引发事故的风险。

-- 产品本体(高介电常数材料层、绝缘层、外半导电屏蔽)采用三层共挤技术,结构紧密,电性 能稳定,避免了传统铸造工艺易产生气孔,质量不稳定的缺陷。

-- 本体挤出生产的同时在线检测电气性能,100%进行局部放电测试。

-- 在连接管上缠绕高介电常数材料,绝缘端部无需椎型处理。

-- 材料采用乙丙橡胶其电气及物理性能优异,抗撕裂强度高,彻底消除了采用硅橡胶材料现场安 装时易撕裂的缺陷。

-- 本体收缩比较大,一个本体可适合多种电缆规格。

-- 特殊的乙丙橡胶配方使本体安装后,对电缆提供持久的径向压力,且随电缆线芯的热胀冷缩一 同变化(与电缆绝缘同呼吸),不产生气隙。

-- 附件的支撑芯有两种方式可供选择:自退式,安装更简捷;抽拉式,可减少安装尺寸。抽拉式 独家采用两端抽拉设计,中心定位准确,且减少支撑芯与电缆线芯的摩擦,不易断裂安全可靠。

-- 安装时不需要特殊工具,不需加热(热缩护套保护除外)连接后可立即通电使用。

-- 附件一经安装,在电缆护套外缠绕的堵水带能使接头本体两端完全密封.具有良好的防水性能.

-- 通常金属屏蔽和钢铠统一接地,如用户要求屏蔽、钢铠单独接地,也可选择单独接地方式。

-- 本产品适用各种地面环境及各类工业环境。

质量保证 -------------------------------------------------------

-- 公司已通过 ISO 9001-2000 质量体系的认证

-- 公司已通过 ISO 14001-2004 环境体系的认证

-- 所有产品均经 100%试验后出厂

标准 ------------------------------------------------------------

本产品符合以下国内和国际相关标准

JB8144-95 ; GB12706.4-02 ; IEC60502-1 ; ANSI/IEEE404 ; NFC 33001 ; DIN 57278

试验 ------------------------------------------------------------

本产品根据国内标准的要求,在国家权威检测机构-武汉高电压研究所(国家电气设备质量检 测中心),通过以下试验项目:

|

序号

|

检测项目

|

标准要求

|

检测结果

|

评注

|

|

1

|

1分钟工频电压试验

|

105kV , 不击穿

|

105kV,1Min,两个组合试样各相均未击穿

|

合格

|

|

2

|

局部放电试验

|

45kV下放电量不大于10pC

|

1号试样放电量<3pC

|

合格

|

|

|

|

|

2号试样放电量<3pC

|

合格

|

|

3

|

负荷循环试验

|

导体加热至 90∽95℃,每一循环为 8h,其中加热 5h 冷却 3h,共三次循环

|

按标准要求完成三次负荷循环试验

|

有以下试验评定

|

|

4

|

局部放电试验

|

45kV下放电量不大于10pC

|

1号试样放电量<3pC

|

合格

|

|

|

|

|

2号试样放电量<3pC

|

|

|

5

|

冲击电压试验

|

250kV,正负极性各10次,不击穿

|

250kV正负极性各10次,两个组合式样,各相均未击穿

|

合格

|

|

6

|

负极性 15min 直流电压试验

|

156kV,不闪络,不击穿

|

156kV,15min, 两个组合试样各相均未击穿

|

合格

|

|

7

|

4h工频电压试验

|

104kV, 不击穿

|

104kV,4h,组合试样各相均未击穿

|

合格

|

选型表 ----------------------------------------------------------

通常 35kV 系统电缆中间接头按以下截面选型,

|

电缆截面(mm2)

|

单芯(热缩管外保护)

|

单芯(铠装带保护)

|

三芯(热缩管外保护)

|

三芯(铠装带保护)

|

|

50~150

|

RTJM-1C-26/35-IP-T2+Hs

|

RTJM-1C-26/35-IP-T2+Ar

|

RTJM-3C-26/35-IP-T2+Hs

|

RTJM-3C-26/35-IP-T2+Ar

|

|

|

|

|

|

|

|

185~500

|

RTJM-1C-26/35-I-T2+Hs

|

RTJM-1C-26/35-I-T2+Ar

|

RTJM-3C-26/35-I-T2+Hs

|

RTJM-3C-26/35-I-T2+Ar

|

|

|

|

|

|

|

|

630

|

RTJM-1C-26/35-I-T2+Hs

|

RTJM-1C-26/35-I-T2+Ar

|

|

|

* 遇其它电压系统或特殊型号电缆应根据电缆绝缘外径选型

包装 ------------------------------------------------------------

本产品在包装箱内提供一整套电缆接头所需的部件(不包括连接管,或由经销商提供),附有完整 的产品操作说明、装箱单、合格证,用户应严格按操作说明安装使用该产品。

储存、运输、安装 -----------------------------------------------

本产品应按以下要求进行储存、运输、安装。

-- 本产品在-10―50℃室内干燥的环境下,储存期为 24 个月。

-- 运输时应防雨、防挤、防砸。

-- 本产品应由经过培训的专业人员进行安装,安装时环境温度为 0―50℃,如超出该温度范围安装, 请与普睿司曼电缆有限公司联系。