PRYSMIAN光纤复合架空地线OPGW光缆

One of PRYSMIAN's top is the world in the field of communication of the manufacturers, the products include: optical fiber, optical cable, optical amplifier, optical submarine cable system and optical device. These ensure that PRYSMIAN provides not only the appropriate cable, and the whole optical communication system. PRYSMIAN provides comprehensive services from design, R & D and production and support for the operation of optical fiber network technology.

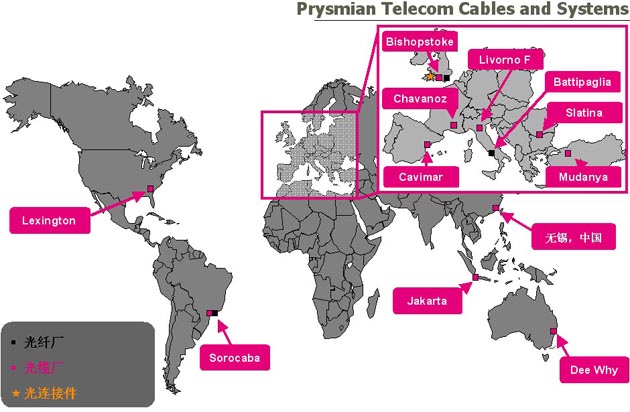

PRYSMIAN has more than 130 years of production experience, and has production plants in 4 continents, 12 countries in the world, the PRYSMIAN has become the backbone of the international market, but also to ensure that the persistence of the supply capacity and high-end service ability.

PRYSMIAN is the only global technology also has 3 kinds of manufacturing fiber: MCVD (modified chemical vapor deposition method), OVD (gas phase deposition method) and VAD (axial vapor deposition). PRYSMIAN has its unique status in the three major manufacturing process, so as to ensure that our products are suitable for optical fiber application environment of different.

PRYSMIAN在通信领域也是世界上顶级的厂家之一,其产品包括:光纤、光缆、光放大器、海底光缆系统以及光器件。这些确保PRYSMIAN提供的不光是合适的光缆,还有整套光通信系统。PRYSMIAN提供的全面服务从设计、研发及生产以至对投运光缆网络的技术支持。

PRYSMIAN拥有130多年的生产经验,以及在全球4个大洲、12个国家拥有生产企业,使PRYSMIAN已成为国际市场的中坚力量,同时也确保了其供应能力以及高端服务能力的持续性。

PRYSMIAN是全球唯一同时拥有3种光纤制造工艺技术:MCVD(改进的化学气相沉积法)、OVD(外气相沉积法)和VAD(轴向气相沉积法)。PRYSMIAN在三大制造过程中有其独特的地位,从而确保我们的光纤产品适合于不同的环境应用。

The PRYSMIAN global optical fiber and optical cable, optical amplifier, optical submarine cable system and optical device manufacturing enterprises

PRYSMIAN遍布全球的光纤、光缆、光放大器、海底光缆系统以及光器件生产企业

Structure of Combined Science

High anti lightning performance

Good protection of optical fiber

All kinds of characteristics of superior

The superior corrosion resistance, all metal surfaces for aluminum, conductive, low temperature rise, better heat dissipation performance.

The 1PRYSMIANOPGW product design

According to the OPGW as a dual function of ground wire and optical communications, PRYSMIAN to provide high quality products with superior performance.

As optical communication function, like an ordinary cable, the optical fiber is arranged in the middle not cable, the outer layer of protection. Different from the common cable transmission lines, the operating environment in the long term under the bad, through a series of strong measures to reduce the high temperature, low temperature, effect of tensile stress, material aging and corrosion of the optical fiber, so that the optical fiber in OPGW has a longer service life.

- as the ground function, symmetry, the outer layer of aluminum clad steel wire, pay attention to the anti lightning performance, maximize its mechanical, physical, electrical, chemical properties.

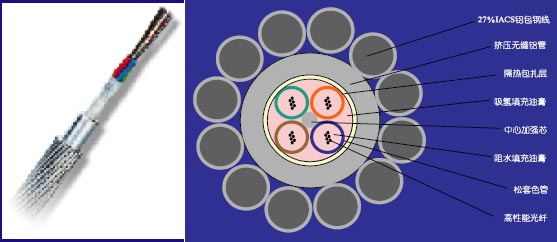

The structure characteristics of 2 PRYSMIANOPGW

Optical unit tube adopts thick extruded aluminum tube, so as to ensure its long-term tightness.

Optical unit optical fiber loose tube, twisted reinforcement in non metal center, fiber paste filled with water resistance effect, and has more than enough long uniform.

- contact surface is the same for all metal metal, which can completely avoid corrosion electrochemical possible contact between the different metals.

Optical unit tube filling hydrogen absorption ointment.

- in the inner wall of heat insulating protection optical unit tube belt

Optical unit pipe wall thickness, diameter, short circuit capacity, tensile strength, according to the OPGW diameter, nominal tensile force, short circuit current capacity of the user defined, by adjusting the light unit tubes with the wall thickness and diameter, the choice of electrical conductivity of 20,3-27%IACS aluminum clad steel outer wire, is easy to realize the outer aluminum clad steel, the outer layer large diameter OPGW single product, without using special thickened layer of aluminum aluminum clad steel wire, so as to improve the anti lightning performance, and not change the design idea, than reinforced aluminum layer of aluminum clad steel outer wire better mechanical properties, anti lightning performance is stronger.

Figure 1 PRYSMIAN-OPGW typical structure diagram

3 high anti lightning performance

According to the OPGW diameter, nominal tensile force, short circuit current capacity of the user defined, by adjusting the light unit tubes with the wall thickness and diameter, the choice of electrical conductivity of 20.3-27%IACS aluminum clad steel outer wire, very easy to achieve outer aluminum clad steel, outer wire diameter large OPGW products, without the use of special thickened layer of aluminum aluminum clad steel line, so as to improve the anti lightning performance, and not change the design idea, than reinforced aluminum layer of aluminum clad steel outer wire mechanical performance is better, stronger anti lightning performance.

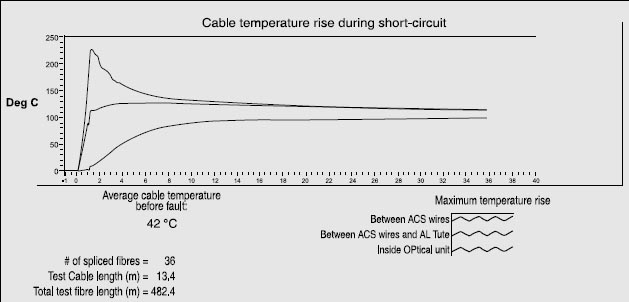

Optical fiber in -PRYSMIANOPGW, because the outer aluminum clad steel wire, heat absorption and barrier of thick wall aluminum heat dissipation, heat insulation bundling belt and optical fiber loose tube heat insulation, when the lightning, the temperature rise is very small, well protected.

The light unit in -PRYSMIANOPGW, because the outer aluminum clad steel wire, heat absorption and barrier of thick wall tubes in the heat, when the lightning, the temperature rise is small, the damage probability is very small.

DC resistance of -PRYSMIANOPGW is slightly larger than the other one ground wire, in order to reduce the probability of OPGW was struck by lightning.

According to the test standard of 60794-4-1-1999 - IEC, PRYSMIANOPGW proved that the charge of 200 Kulun lightning conditions aluminum tube in the middle level of the transfer quantities through test,

In OPGW stranding process, through scientific calculation and strict control of stranding process, even if the outer strand broken, not easy to loose, so as to avoid the damage caused by short circuit of power system.

4 superior fiber characteristics

-PRYSMIAN is today the only also has MCVD, OVD and VAD three kinds of technology production and suppliers.

Single mode fiber after prolonged - Test of not less than 1%, the Weibull of the optical fiber index greater than 19.

With the optimal value of PMD, line PMD can achieve the level of 0.07ps/.

Use NeonTM coating improved the fatigue parameters of fiber, improve the service life of the optical fiber; NeonTM coating material itself contains a color, reduce the color process, avoid the damage caused by the optical fiber detection after (this damage is brought to the OPGW product, latent hazard).

The transmission attenuation of low -. 1310nm "0.34dB/km; 1550nm" 0.20dB/km.

Bending low attenuation. 25mm the radius of 100 circle, 1550nm bending attenuation "0.05dB.

Temperature characteristics of optical fiber coating.

Optical fiber protection 5 good

Different from the common cable, improve the OPGW life, the most fundamental is to improve fiber life, is mainly to improve the tensile strength, fiber static fatigue parameter and high temperature resistant performance.

5.1 high temperature resisting superior performance

Optical unit in protection of two layers of metal under a layer of aluminum clad steel wire - cable provides excellent mechanical properties, high purity aluminum - cable provides electrical and thermal properties to protect the best, all of these cable provides lightning resistance performance of the best.

- under the same conditions, extrusion aluminum tube OPGW cable shows more excellent performance, even at high intensity of lightning conditions, the light unit OPGW cable aluminum tube structure is not compromised, this is because the conductive and heat dissipation properties of aluminum is better than stainless steel; therefore, aluminum can be completely and quickly absorbed and the transfer of the arc current and energy, so as to reduce the damage, protect the light unit.

Optical fiber temperature rise:

5.2 anti fatigue parameters

-PRYSMIAN patented technology of hydrogen absorption ointment to avoid damage to the optical fiber hydrogen ion.

Extrusion manufacturing thick wall tube with light unit air tightness of the long-term, to prevent the intrusion of moisture and moisture.

-PRYSMIAN optical cable optical fiber dynamic fatigue parameter can reach above 26.

5.3 good tensile property

Optical fiber loose tube manufacturing process, manufacturing contraction formed long yu.

- layer stranded optical fiber loose tube, when the OPGW is stretched (or contraction), optical fiber loose tube center position (from inward or outward) length change can produce mobile.

- the center of the optical fiber, stranded

6 superior corrosion resistance

In OPGW optical cable technology used in extrusion molding aluminum structure cables, all metal surfaces are of the same kind of metal aluminum, so it will not produce electrolytic corrosion. Guarantee in mechanical, electrical performance index in the service life of OPGW.

- while in the stainless steel tube structure (according to the standard should not use insulating ointment), different metal (steel and aluminum) may come into contact with each other, thereby producing electrolytic corrosion. Stainless steel pipe and aluminum clad steel wire coated aluminum electrochemical potential difference, so easy to appear the phenomenon of electrochemical corrosion. Some steel structure suppliers by insulating ointment to prevent electrolytic corrosion is filled in between the steel tube and the armor wire. However, these ointment may be due to the high temperature produced by large current and fall, may also move due to vibration and temperature changes. So, using the ointment can not completely guarantee to avoid the occurrence of electrolytic corrosion, corrosion protection of steel structure is the best light unit uses the aluminum clad steel pipe.

The 7 type test superior various characteristics

-PRYSMIAN laboratory have their own, can be completed in addition to short-circuit test outside the OPGW type almost all tests, including lightning test. Therefore, we can provide all kinds of cable type test report form complete.

The electrical properties of -OPGW (performance including performance and tolerance of lightning withstand short-circuit current.).

The environmental performance of -OPGW (including temperature attenuation, drip test and seepage properties) project.

8 OPGW connection box for superior performance

- in order to ensure the working life of the junction box should be greater than OPGW life and protection of optical fiber, junction box, PRYSMIAN is designed for OPGW optical cable terminal box design, with mature technology, can not only has good dustproof, waterproof and antirust performance, but also has the anti compression, anti collision and ballistic performance.

- type test report, complete include: static bearing test, impact test, slump test pressure test (IP X7), waterproof, dust-proof test (IP 6X), prevent the waterproof test shooting test, corrosion test and temperature cycling test and pressure in the.

9 of the global sales of large

Experience in research and development of -25, PRYSMIAN (formerly the Pirelli) since 1989, production and supply of the first OPGW cable PRYSMIAN OPGW cable start, engaged in the development, design and production has been nearly 25 years

- so far, PRYSMIAN company has to global customers to provide more than 64000 kilometers of fiber optic cable, which is used in China for more than 6000 kilometers.

-PRYSMIAN in 2001-2003, in the global sales of 25088.6 kilometers, 2004 sales reached: 15000 km.

10 after-sales service

- timely, construction supervision, technical support for installation and debugging, technical assistance, calibration, training and other similar obligations.

PRYSMIAN(比瑞利)OPGW

Optical Fiber Composite Overhead Ground Wire

(光纤复合架空地线)

科学的结构组合

高抗雷击性能

很好地保护光纤

优越的各类特性

优越的耐腐蚀性能,所有金属接触面为铝,更佳的导电、散热性能、低温升。

1PRYSMIANOPGW产品设计

-根据OPGW作为地线和光通信的双重功能,PRYSMIAN为此提供性能优越的高质量产品。

-作为光通信功能,象普通光缆一样,将不光纤置于光缆的中部,外层对其保护。不同于普通光缆,在输电线路长期恶劣的运行环境下,通过一系列强有力的措施减小高温、低温、拉应力、材料老化和腐蚀对光纤的影响,从而使OPGW中的光纤具有更长的使用寿命。

-作为地线功能,结构完全对称,外层全铝包钢线,注重抗雷击性能,最大限度地提高其机械、物理、电气、化学性能。

2 PRYSMIANOPGW结构特点

-光单元管采用厚壁挤制铝管,从而保证其长期的气密性。

-光单元管中,光纤松套绞合在非金属中心加强件上,填充纤膏以起阻水作用,并有足够的均匀余长。

-所有金属的接触面是相同的金属,从而可以完全避免不同金属之间接触可能产生的电化学腐蚀现象。

-光单元管内填充吸氢油膏。

-在光单元管的内壁的隔热保护带

-光单元管的壁厚、直径、短路电流热容量、抗拉强度,根据OPGW直径、额定拉断力、短路电流容量的用户限定,通过调节光单元铝管的壁厚与直径、选择导电率为20,3-27%IACS铝包钢外层单线,很容易实现外层全铝包钢、外层单线直径大的OPGW产品,而无须采用特别加厚铝层的铝包钢线,这样既提高了抗雷击性能,又不改变设计理念,比加厚铝层铝包钢外层单线机械性能更好,抗雷击性能更强。

图1 PRYSMIAN-OPGW典型结构图

3 高抗雷击性能

-根据OPGW直径、额定拉断力、短路电流容量的用户限定,通过调节光单元铝管的壁厚与直径、选择导电率为20.3-27%IACS铝包钢外层单线,很容易实现外层全铝包钢、外层单线直径大的OPGW产品,而无须采用特别加厚铝层的铝包钢线,这样既提高了抗雷击性能,又不改变设计理念,比加厚铝层铝包钢外层单线机械性能要好,抗雷击性能更强。

-PRYSMIANOPGW中的光纤,由于外层铝包钢线对热量的吸收和阻隔、厚壁铝管的散热、隔热包扎带和光纤松套管的隔热,当遭受雷击时,温升非常小,得到了很好的保护。

-PRYSMIANOPGW中的光单元,由于外层铝包钢线对热量的吸收和阻隔、厚壁铝管的散热,当遭受雷击时,温升较小,损伤概率很小。

-PRYSMIANOPGW的直流电阻略大于另一根地线,以降低OPGW被雷击概率。

-按IEC 60794-4-1-1999的试验标准,PRYSMIANOPGW通过试验证明铝管结构在中等水平的雷击条件下200库伦的电荷转移量,

-在OPGW成缆绞合过程中,通过科学计算和严格控制绞合工艺,即使外层断股,也不容易松散,从而避免造成电力系统短路的危害。

4 优越的光纤特性

-PRYSMIAN是当今唯一同时具有MCVD,OVD和VAD三种技术的生产、供应商。

-单模光纤经过不小于1%的延长试验,光纤的Weibull指数大于19。

-具有最优的PMD值,线路PMD可以达到0.07ps/的水平。

-采用NeonTM涂层,提高了光纤的抗疲劳参数,提高光纤的使用寿命;NeonTM涂层材料本身含有颜色,减少了上色工艺,避免了光纤检测后造成的损伤(此损伤被带到OPGW的成品中,潜伏着隐患)。

-低的传输衰耗。1310nm《0.34dB/km;1550nm《0.20dB/km。

-低的弯曲衰耗。25mm半径100圈,1550nm弯曲衰耗《0.05dB。

-光纤涂层的温度特性。

5 很好的光纤保护

与普通光缆不同,提高OPGW寿命,最根本是要提高光纤的寿命,主要是提高光纤的抗拉强度、静态疲劳参数和耐高温性能。

5.1抗高温性能优越

-光单元处于两层金属的保护之下, 一层铝包钢线-为光缆提供极佳的机械性能,一层高纯铝-为光缆提供最好的电气、热学性能保护,所有这些为光缆提供最好的抗雷击性能。

-而相同条件下,挤压成型铝管结构的OPGW光缆表现出更加优异的性能,即使在高强度雷击条件下,铝管结构的OPGW光缆的光单元也不会受到损害,这是因为铝比不锈钢具有更好的导电、散热性能;所以,铝管能够完全、迅速地吸收、转移电弧电流和能量,从而降低损害,保护光单元。

-光纤的温升:

5.2抗疲劳参数好

-PRYSMIAN享有专利技术的吸氢油膏避免氢离子对光纤的损害。

-挤压制造的厚壁光单元管具有长期的气密性,防止潮气和水分的侵入。

-PRYSMIAN光缆的光纤的动态疲劳参数可达26以上。

5.3抗拉性能好

-光纤松套管制造过程中,冷缩形成的制造余长。

-层绞式光纤松套管,当OPGW被拉伸(或收缩)时,光纤从松套管中心位置向内(或向外)移动所能产生的长度变化。

-中心光纤,层绞式

6 优越的耐腐蚀性能

-在常用的OPGW光缆工艺中的挤压成型铝管结构的光缆组成中,所有金属接触面都是同一种金属-铝,所以不会产生电解腐蚀。保证在使用寿命内OPGW的机械、电气性能指标。

-而在不锈钢管结构中(按照标准不应使用绝缘油膏),不同的金属(钢和铝)可能相互接触,从而产生电解腐蚀。不锈钢管与铝包钢线的包铝存在电化学电位差,所以容易出现电化学腐蚀的现象。一些钢管结构的供应商通过在钢管和铠丝之间填充绝缘油膏来避免电解腐蚀。但是,这些油膏可能由于大电流产生的高温而滴落,也可能由于振动和温度的变化而移动。所以,使用油膏并不能完全保证避免电解腐蚀的发生,钢管结构最好的防腐保护是使用铝包钢管的光单元。

7 型式试验优越的各特性

-PRYSMIAN有自己的试验室,能完成除短路试验外几乎所有的OPGW型式试验,包括雷击试验。因此,我们能提供各种缆型完整的型式试验报告。

-OPGW的电气性能(主要包括承受短路电流的性能和耐受雷击的性能)。

-OPGW的环境性能(包括温度衰减特性,滴流试验和渗水性能等)项目。

8 OPGW的接续盒性能优越

-为了保证接线盒的工作寿命应大于OPGW的寿命及对光纤的保护,PRYSMIAN专为OPGW光缆设计的接线盒,终端盒,采用成熟的工艺技术,不但可以具有良好的防尘、防水和防锈性能,而且具有防挤压、防冲撞及防弹性能。

-完整的型式试验报告,包括:静态承压试验、冲击承压试验、滑落试验、防水试验(IP X7)、防尘试验(IP 6X),防枪击试验、防腐试验、温度循环试验及水压下的防水试验。

9 全球销售量大

-25的研发经验,PRYSMIAN(原比瑞利)自从1989年生产、供应第一条OPGW光缆开始,PRYSMIAN从事OPGW光缆的研发,设计和生产已经近25年

-至今,PRYSMIAN公司已经向全球客户提供了超过了64,000公里的光缆,其中在中国使用的就超过6,000公里。

-PRYSMIAN在2001-2003年间,在全球的销售量为25,088.6公里,2004年销售量达:15,000公里。

10 售后服务

-及时、施工督导、技术支持安装、调试、技术协助、校准、培训以及其他类似的义务。

Prysmian optical fiber composite overhead ground wire of OPGW cable