Leroy-Somer Liquid(water/oil) cooled motors Marine LC 355 450KW LC500 1500KW

LC series Compact design: Space, weight and dimensions can be as much as 25% less than an air-cooled motor.

Energy Savings The liquid cooling system of LC motors is provided by water circulation over the frame housing.

Customer benefits

Performing Design

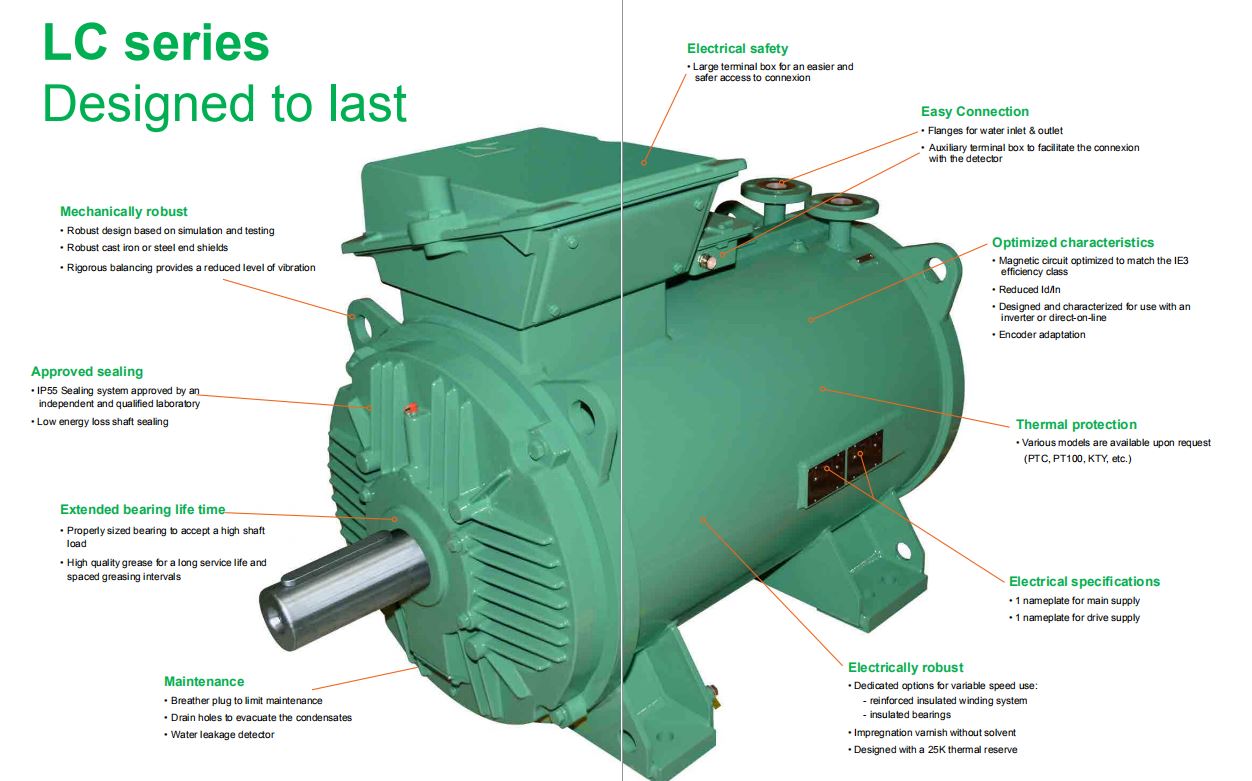

Whatever the conditions are, the LC series has been designed for a clean environment (IP55) or harsh

environments (IP56/65). Based on the success and reliability of the IMfinity platform, the LC motors achieved the highest electrical and mechanical performances, including some innovative characteristics:

•Modern housing allowing excellent heat dissipation

•Sophisticated cooling system reducing the noise level

•Improved modularity thanks to its fabricated steel design

•Patented breathable membrane that ensures continuity in production and low or no maintenance

Cost-effective adaptability

•Its liquid cooled design enables:

-higher power in an equivalent standard motor frame size

-compactness of the motor for easier and less costly integration within a machine or a system

-no need for any external component, such as ventilation

Combined with the high efficiency level of the motors, it particularly allows a quick Return On Investment

•Ideal for DC motor retrofit (for a reduced maintenance cost)

Compact design: Space, weight and dimensions can be as much as 25% less than an air-cooled motor.

Reduced Noise level

The LC series has been designed to significantly decrease the noise level by -10 to -20 dB (A) compared to air-cooled

motors

Patented high performance membrane

LC motors are delivered with a waterproof breather plug. This type of PTFE membrane is air and steam

permeable, but perfectly tight to liquids (mini IP66).

Usually, in liquid cooled motors, the cooling liquid circulates around the motor submitting it to a huge difference in temperature. Depending on the environmental conditions, the condensation generated can be very significant and can damage the motor if not treated.

LC motors have draining holes and thanks to their performing patented breathable waterproof membrane the maintenance operations are dramatically reduced.

The breather plug regulates the condensation level in a time and cost-effective way:

•Reduced machine downtime maximizing production continuity

•Decreased maintenance cost

LC series

Clever simplicity

Energy Savings

The LC series has been designed to achieve the efficiency levels defined in IEC 60034-30-1 standards. As standard, LC motors are IE3 Premium from 150 to 1500 kW.

Ready for heavy-duty applications

The liquid cooling system of LC motors is provided by water circulation over the frame housing.

This system maintains the thermal efficiency, enabling the motor to be used together with a drive, from low to high speed, for heavy-duty applications that require constant torque.

•Cooling circuit: IC71W

•Frame: steel, jacket cooled

•Liquid inlet /outlet: by flanges or threaded holes

•Windings impregnated with VPI system

Variable speed application

The LC motor has been designed integrating specific features as standard:

• Thermal reserve for maintaining the rated torque over an extended speed range In order to meet particular requirements, options can be provided upon request:

•Reinforced winding insulation and insulated bearings for main voltages > 400 V, long cable lengths and frequent operation during the braking phase

•Motors can be equipped with an encoder for applications that require precise positioning

Standard features

- Frame sizes: 315 to 500 (< 315 and > 500 on request)

- Voltage: 400V for 315 to 450 mm / 690V for 500 mm

- Number of poles: 2, 4 & 6

- Frequency: 50 or 60 Hz

- Insulation class: F or H

- Mounting: B3, B35 and V1 (other position on request)

- Double nameplate: DOL + variable speed characteristics

- Water leakage detector

Main optional features

- Insulated DE & NDE bearings

- Winding and endshield thermal protections (PT100, CTP, KTY or others)

- Encoder

- Space heaters, etc.

Special features

- Marine certification: ABS, Lloyd’s, DNV, BV, etc.

- Conformity cURus (winding insulation system)

Output power per frame size (f = 50 Hz)

IE3 Premium Efficiency Motors

|

|

3000 rpm

|

|

1500 rpm

|

|

1000 rpm

|

|

Type

|

kW

|

Type

|

kW

|

Type

|

kW

|

|

LC 315 LA

|

220

|

LC 315 LA

|

220

|

LC 315 LA

|

150

|

|

LC 315 LB

|

250

|

LC 315 LB

|

250

|

LC 315 LB

|

170

|

|

LC 315 LKA

|

315

|

LC 315 LKA

|

315

|

LC 315 LKA

|

270

|

|

LC 315 LKB

|

355

|

LC 315 LKB

|

355

|

LC 315 LKB

|

315

|

|

LC 315 LKC

|

400

|

LC 315 LKC

|

400

|

LC 355 LA

|

270

|

|

LC 355 LA

|

400

|

LC 355 LA

|

400

|

LC 355 LB

|

315

|

|

LC 355 LB

|

450

|

LC 355 LB

|

450

|

LC 355 LKA

|

355

|

|

LC 355 LKA

|

550

|

LC 355 LC

|

500

|

LC 355 LKB

|

400

|

|

LC 355 LKB

|

700

|

LC 355 LKA

|

560

|

LC 355 LKC

|

500

|

|

|

|

LC 355 LKB

|

630

|

LC 400 LA

|

500

|

|

|

|

LC 400 LA

|

750

|

LC 400 LB

|

650

|

|

|

|

LC 400 LKA

|

850

|

LC 400 LKA

|

850

|

|

|

|

LC 450 LA

|

1000

|

LC 450 LA

|

950

|

|

|

|

LC 450 LB

|

1200

|

LC 450 LB

|

1050

|

|

|

|

LC 500 L

|

1500

|

LC 500 M

|

1300

|

LC motors are particularly recommended for Plastics & Rubber, test rigs and Marine applications.

Typical industries:

Plastics & Rubber Marine

Test Rigs Industrial Refrigeration

Printing Glass

Food & Beverage Metals

Port Logistics Nuclear power

Packaging Water Textile

Liquid-cooled motors are particularly suitable for and are used in applications requiring a low noise level, high output power with IP55 protection, compact dimensions and operation on a drive.

Advantages

-Motor cooled by a water circuit integrated in the housing (IC71W)

-Reduced noise level: the water cooling system means the fan is no longer necessary and ensures a reduced noise level (between 60 and 80 dB (A) in LpA

-IE3 Premium efficiency across the whole range: 150 to 1500 kW - 2, 4 & 6-pole

-Compact design: weight and dimensions can be as much as 25% less than an air-cooled IP55 motor, and as much as 55% less than an IP55 motor cooled by an air/water exchanger (IC81W)

-Degree of protection higher than IP55 (e.g.: IP56) as an option

-Motor adapted for use at constant torque across the entire speed range from 0 to 50 Hz, without derating. The motor is always cooled, whatever the point of operation.

-Reduced vibration level

-Heat recovery thanks to dissipation of losses by an external water circuit

Application areas

-Marine: main propulsion and bow thruster units, equipment on the bridge of the ship

-Test benches: automotive, aeronautics

-Pumps, compressors, agitators, mixers

-Plastics industries: extrusion and plastic injection machines

-Hydraulic turbines

Heavy industries: iron and steel, cement, chemical industries